- Industrial machines and equipment

- Welding and Assembly

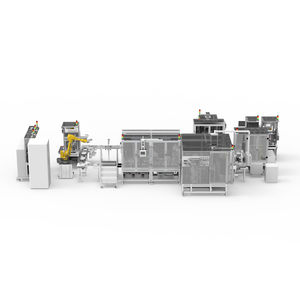

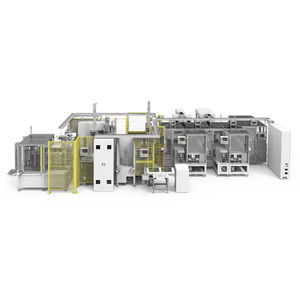

- Automatic assembly line

- TZTEK Technology Co.,ltd

Automatic assembly line markingpackagingfor water pumps

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Associated function

- packaging, marking

- Applications

- for water pumps

Description

• The production line of the project consists of 5 lines: stator line, assembly line, rotor line, sampling line and packaging line. The core processes of production lines include automatic loading and unloading by vision-guided robot, laser marking, stator winding, servo press fitting, 3D & 2D camera detection, laser line scanning and detection, hot riveting, and stator performance test.

Benefit Advantages

• Unmanned automatic production to reduce labor costs for factories and improve productivity and consistency of production

• Whole process quality control of the product parts from the incoming materials to the finished products, with the assembly yield2 99% through vision, sensors, standard instruments and other measurement and monitoring means

• Production pace: Daily output of 4800 electronic water pumps and annual output of 1.7 million pumps for customers at a speed of 15s/piece

• Real-time online monitoring of the product production process and the production line status by data traceability system of the production process via network, to ensure the traceability of the quality data of the whole process of product assembling and testing and the efficiency of the production line

Related Searches

- Assembly line

- Automated assembly line

- Adhesive dispensing machine

- Test assembly line

- Flexible assembly line

- Marking assembly line

- Inspection assembly line

- Packaging assembly line

- Fully-automatic glue dispensing machine

- Compact glue dispensing machine

- Glue dispensing machine for the electronics industry

- Glue dispensing machine with inspection system

- Actuator assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.