- Industrial machines and equipment

- Welding and Assembly

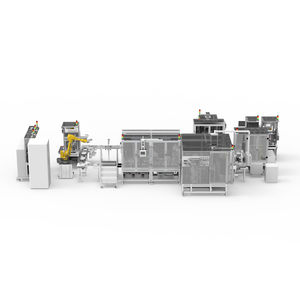

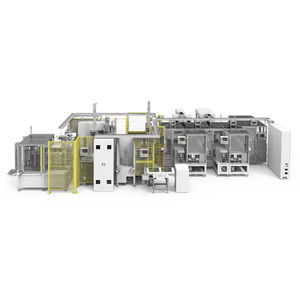

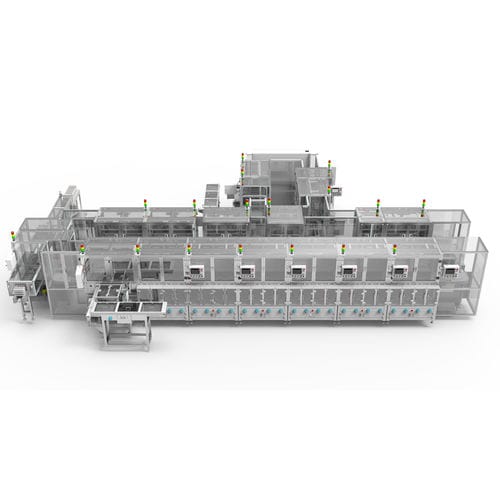

- Automatic assembly line

- TZTEK Technology Co.,ltd

Automatic assembly line testfor shock absorber

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Applications

- test, for shock absorber

Description

The project consists of three lines, the first line for assembling of the connecting rod sub-assembly, the second line for assembling of the cylinder barrel sub-assembly, and the third line for the combined assembling, in which there are 23 stations across the whole line, and the core processes include connecting rod riveting, vacuum oiling, outer cylinder sealing, assembly inflation, and force value testing.

Benefit Advantages

• Three modules flexibly configured to complete different product sub-assemblies

• Capable of in-line testing and loading testing

• Compatible with different product types

• MES system enabling accurate traceability of large parts and traceability of small parts to batches

Related Searches

- Assembly line

- Automated assembly line

- Adhesive dispensing machine

- Test assembly line

- Flexible assembly line

- Inspection assembly line

- Marking assembly line

- Packaging assembly line

- Compact glue dispensing machine

- Fully-automatic glue dispensing machine

- Glue dispensing machine for the electronics industry

- Glue dispensing machine with inspection system

- Actuator assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.