- Industrial machines and equipment

- Welding and Assembly

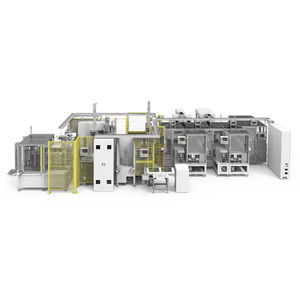

- Automatic assembly line

- TZTEK Technology Co.,ltd

Automatic assembly line inspectionfor hydraulic brake caliper

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Associated function

- inspection

- Applications

- for hydraulic brake caliper

Description

• The line is used for assembling and testing of dual-piston hydraulic calipers with 22 stations. The core processes include gas tightness testing, press fitting, oiling, screw driving and visual inspection.

Benefit Advantages

• Except for some large materials, the rest are automatic stations, making the whole line highly automated

• Fast production pace, high flexibility with robots in key parts, and high compatibility at a later stage

• New production line to improve quality control requirements with full traceability of the process

Related Searches

- Assembly line

- Automated assembly line

- Adhesive dispensing machine

- Test assembly line

- Flexible assembly line

- Marking assembly line

- Inspection assembly line

- Packaging assembly line

- Fully-automatic glue dispensing machine

- Compact glue dispensing machine

- Glue dispensing machine for the electronics industry

- Glue dispensing machine with inspection system

- Actuator assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.