- Industrial machines and equipment

- Welding and Assembly

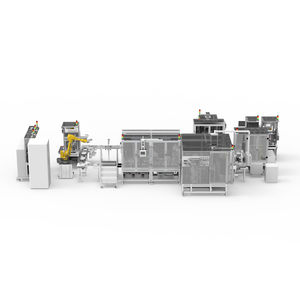

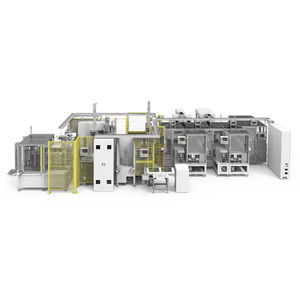

- Automatic assembly line

- TZTEK Technology Co.,ltd

Automatic assembly line markinginspectiontest

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Associated function

- inspection, marking

- Applications

- test, for actuators

Description

• Automatic marking hot sleeve servo press fitting for stator loading, stator de-lacquering and straightening, resistance welding after manual installation of connectors, bearing press fitting, automatic loading IPG laser welding for motor cover bearing, performance testing before stator loading, automatic marking hot sleeve servo press fitting for stator loading, stator delacquering

and straightening, resistance welding station after manual installation of connectors, automatic glue curing for stator, PCB press fitting hot riveting station, PCB pin size inspection after press fitting, stator and rotor assembly servo press fitting, seal sheet de-oxidation layer automatic feeding IPG welding, tooth groove, counter-electromotive force test, motor connector

electric declination adjusting, motor performance test, motor air-tight test, weighing and packing for unloading.

Benefit Advantages

• Flexible production, compatible with both gearshift and gear selector models, with a changeover time s 120s

• Whole process quality control from the incoming materials to the finished products, with the assembly yield 299%

• First assembly line of loading loose motor parts and assembling finished products off the line

• Daily output of 2000 electronic actuator motors in a single shift for customers at a assembling speed of 20s/piece

• Real-time online monitoring of the production process and production line status by process data traceability system via network, to ensure the traceability of the quality data of the product assembling and testing as well as the efficiency of the production line

Related Searches

- Assembly line

- Automated assembly line

- Adhesive dispensing machine

- Test assembly line

- Flexible assembly line

- Marking assembly line

- Inspection assembly line

- Packaging assembly line

- Fully-automatic glue dispensing machine

- Compact glue dispensing machine

- Glue dispensing machine for the electronics industry

- Glue dispensing machine with inspection system

- Actuator assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.