- Metrology - Laboratory

- Metrology and Test Equipment

- Transmission rate tester

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

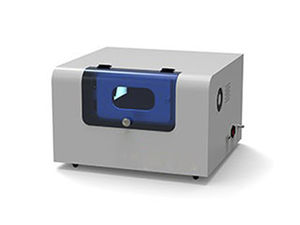

Oxygen transmission rate tester DPG-V2detectorwith pseudo-random signal intensification-polarization

Add to favorites

Compare this product

Characteristics

- Test type

- for oxygen transmission rate

- Tested product

- detector

- Other characteristics

- with pseudo-random signal intensification-polarization

Description

It is applied to various gas permeation rate detection, such as O2,CO2,N2 and air, etc, in plastic film, composite membrane, High-barrier materials, sheet, metal foil, rubber, etc.

Operating principle:

Using the principle design of differential pressure method, put treated sample in the middle of upper and bottom chamber in advance. Pressure tightly and seal, pick up the suction to the whole system, after reaching the required vacuum degree, close bottom chamber, fill with certain test gas to high pressure chamber, and adjust upper chamber pressure, keep on two sides of the sample forming constant air pressure gradient difference, the gas is under the action of differential pressure gradient, permeating from high-pressure side (upper chamber) to vacuum side (bottom chamber). Accurately measure vacuum chamber (bottom chamber) intensity of pressure variation, calculate various barrier property parameters of test sample. Fully conform to the standard ASTM D1434.

Application characteristic

High speed vacuum ability, reduce the vacuum time, degassing more thoroughly, reduce the test error.

Short test time, high efficiency;

Could extend to test bottle, bag;

Save when power failure functions;

Little gas consumption, one bottle of gas could be used for one month continuously.

A whole-process monitor, automatic recording, sampling rate could be adjusted, automatically repeat the test.

The whole process could reappear in whole process, Strong graph curve function, convenient for comparison test and analysis;

Catalogs

No catalogs are available for this product.

See all of U-Therm International (H.K.) Limited‘s catalogsOther U-Therm International (H.K.) Limited products

Packing test

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Portable testing system

- Benchtop indentation hardness tester

- Compression test machine

- Universal test machine

- Digital measuring device

- Digital testing system

- Tensile test machine

- Flexure testing machine

- Thickness measuring machine

- Portable measuring device

- Industrial testing system

- Rockwell indentation hardness tester

- Vickers indentation hardness tester

- Automatic testing system

- Hydraulic test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.