- Machine-tools

- Finishing Machine

- Metal polishing machine

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

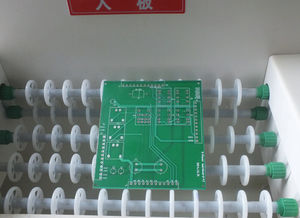

Metal polishing machine SUNY-ZPG500PCBautomatic

Add to favorites

Compare this product

Characteristics

- Machined material

- for metals

- Applications

- PCB

- Other characteristics

- automatic

Description

Specification:

1. Product usage: automatic buffing processing of PCB surface;

2. Main functions: double screw adjusting wheel; electrical automatic control and water drainage; transmission guide rail dismantling, automatic transmission;

3. Brush board method: single, double buffing

4. Control system: high-performance ARM embedded processor + embedded operating system, human-computer interface: big screen color LCD screen + touch screen; In touch screen you can read electronic edition production buffing process manual; In touch screen you can play the circuit board design sketch after buffing process;

5. Brush roller type: Φ110mm 320#;

6. Brush board dimension: width≤400mm length≥100mm;

7. Brush board thickness: 0.5mm~6mm adjusted through the hand wheel;

8. Drying power: 4KW;

9. Transmission motor: 0.5HP, 0.2M~10M/ stepless speed regulation;

10. Power supply: AC380V/50Hz;

11. Entire machine power: 7KW (about 3KW with drying function off);

12. Optional configuration: Ethernet interface, realizing remote diagnosis, monitoring, booking open and close the machine and etc. through the wireless or local area network and the Internet, seamless connection with network management system and software, mating PCB network management software, providing long-term free upgrades service;

13. Dimension: 1710mm×820mm×1090mm

14. Weight: 230 kg.

Catalogs

PCB making machine

156 Pages

Other U-Therm International (H.K.) Limited products

PCB making machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.