- Products

- Automatic laminator

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic laminator SUNY-ZXY500

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

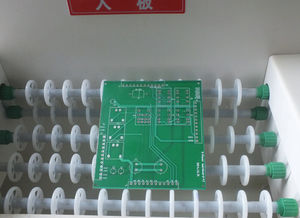

Full automatic spray imaging machine SUNY-ZXY500

Usage: realizing imaging process of the circuit board processing through high pressure spraying and automatic transmission;

Control system: high-performance ARM embedded processor + embedded operating system, human-computer interface: big screen color LCD screen + touch screen; In touch screen you can read electronic edition imaging process manual ; In touch screen you can play the video file in imaging process;

The machine adopts anticorrosive PVC material, with excellent anti acid and alkali performance

The roof and the front of the machine both have double completely transparent glass windows, so the whole process can be observed;

With level automatic in board detection function, it can stop automatically in a due time, to make the machine operation more intelligent and automatic;

With up and down spraying pressure testing and adjustment function, it can make some adjustment to up and down spraying pressure according to the technical requirements;

With liquid level instruction window, you can understand the liquid level of the machine in real-time;

With automatic imaging, liquid isolation, automatic water washing, liquid blotting of board surface and other functions, realizing clean and environmental protect production of the PCB;

The effective work area: double-sided plate of 400 mm width; double-sided plate of unlimited length;

Working mode: PCB automatically in and out board, automatic high pressure spraying up and down double-sided;

Work time: 10~240s adjustable

Temperature setting: 20~55°C;

Standard volume: 50L;

Power supply: AC380V/9KW;

Overall dimension: 1420mm×1020mm×1320mm;

Net weight: 200KG.

Catalogs

PCB making machine

156 Pages

Other U-Therm International (H.K.) Limited products

PCB making machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.