- Production Machines

- Machine for the electronics industry

- SMT pick-and-place machine

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

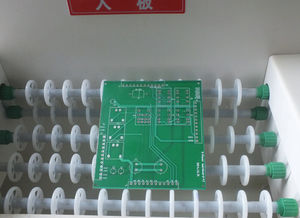

SMT pick-and-place machine SUNY-ITP2050

Add to favorites

Compare this product

Characteristics

- Applications

- SMT

Description

Features:

1. Costeffective Two head pick and place machine, the most suitable for large quantities of resistance and capacitance components and SOP, SOIC, QFP and other mixed production.

2.Unique Y axis belt transmission structure, so that the driving force of the movement and direction of travel coincide, reducing resistance, make the working more stable and accurate.

3.Open feeder setting way to make the intelligent optimization method based on artificial optimization to improve production efficiency.

4.Equipped with different feeders can used for the different kind of the elements

5.Mounting head transmission use the Panasonic servo motor with high-precision guide rail to take the pick and place more stable, fast.

6.Configuring a proprietary structure mounting heads 2groups, the structure is smart, the weight of mounting heads less than 800g, operate more quickly.

7.Special cooling equipment design allows continuous operation, the unique electrical system design, easy maintenance and system maintenance.

8.Circuit board drive using high-precision high speed servo motor drive industrial belt to achieve, effectively improve the chip accuracy and circuit board speed.

9.With the industrial computer and special software control, easy to operate and practical.

10.The software is simple to operate, easy to learn and user-friendly in English.

11.Automatic visual programming software online, without having to manually input the coordinates of components, programming is simple, easy for beginners convenient and practical, high-volume production of many varieties of demands. Simple setup, you can achieve PCB jointed board programming and placement.

Catalogs

No catalogs are available for this product.

See all of U-Therm International (H.K.) Limited‘s catalogsOther U-Therm International (H.K.) Limited products

PCB making machine

Related Searches

- Marking machine

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- SMT pick-and-place system

- Printed circuit marking machine

- Automatic pick-and-place system

- Wave soldering machine

- PCB etching device

- Chemical PCB etching machine

- Automatic PCB etching machine

- Tinning machine

- PCB production machine

- Exposure system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.