- Production Machines

- Additive Manufacturing, 3D Printing

- Model making prototyping machine

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

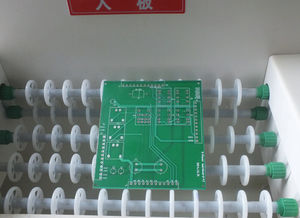

PCB prototyping machine SUNY-ZGK320for model making

Add to favorites

Compare this product

Characteristics

- Applications

- for PCB, for model making

Description

Products: PCB through-hole machine, PCB Machine - PCB Prototype Machine,Small PCB making machines

Model: SUNY-ZGK320

1. Usage: double-sided perforative aperture copper sinking and copper plating to the double-sided circuit board and other non-metal materials;

2. Function characteristics: air-blowing and precoated of copper plating, electroplating short circuit and no plating open circuit testing; constant temperature and heating temperature control with double temperature-control protection, automatic through-hole function, to ensure the conduction rate of through-hole; with opening cover detection, better protecting the safety of the operator

3. Structure features: transparent roof, convenient for operation and observation; self-contained universal caster wheel, convenient for carrying; eight processing grooves, high degree of automation of PCB through-hole operation; negative pressure through aperture structure, automatic through aperture operation function; with double-sided spray water structure, realizing the automatic washing function of PCB;

4. Through-hole technology: advanced black-aperture process, without environmental pollution;

5. Processing dimension: 400mm×300mm;

6. Electroplating power: all control positive and opposite direction pulse electroplating power supply, the current range: 0~30A, adjustable 0.1 A step value, voltage: the highest DC6V

7. Air pump parameters: gas flow: 30L/min;

8. Negative pressure air pump: power 1000W vacuum suction: 210Bar; gas flow: 48L/min;

9. Input power: AC220V/50Hz;

10. Entire machine power: 2200W;

11. Overall volume: length 970mm×width 750mm×height 720mm;

12. Weight: 80Kg (liquid not contained).

Catalogs

No catalogs are available for this product.

See all of U-Therm International (H.K.) Limited‘s catalogsOther U-Therm International (H.K.) Limited products

PCB making machine

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.