- Environment - Health - Safety

- Air Treatment and Noise Management

- Oxidizer

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Oxidizer SUNY-ZYH420

Add to favorites

Compare this product

Description

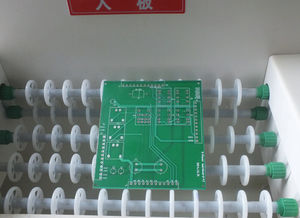

OSP anti-oxidation machine SUNY-ZYH420

1. Purpose: OSP processing to surface welding plate of the circuit board, in order to achieve anti-oxidation and welding-assisting;

2. The process: SMT lead-free forming film technology

3. Configuration: including oil removing, micro erosion, forming film, DI water washing and water washing five process tanks;

4. Process dimension: 400mm×350mm double-sided board

5. Control system: high-performance ARM embedded processor + embedded operating system, human-computer interface: big screen color LCD screen + touch screen; In touch screen you can read electronic edition OSP process manual; In touch screen you can play the circuit board design sketch after OSP process;

6. Oil removing tank: equipped with anticorrosive isolation circulating pump, making the liquid do convection work, in order to achieve the best oil removing effect;

7. The erosion tank: equipped with liquid convection device in order to achieve the best effect of erosion;

8. Forming film tank: equipped with anticorrosive isolation circulating pump, making the liquid do convection work, in order to achieve the best effect of forming film;

9. Optional configuration: Ethernet interface, realizing remote diagnosis, monitoring, booking open and close the machine and etc. through the wireless or local area network and the Internet, seamless connection with network management system and software, mating PCB network management software, providing long-term free upgrades service;

10. Input power: AC220V/50Hz

11. Entire machine power: 2500W

12. Overall volume: 1120mm×820mm×910mm

13. Net weight: 135KG.

Catalogs

No catalogs are available for this product.

See all of U-Therm International (H.K.) Limited‘s catalogsOther U-Therm International (H.K.) Limited products

PCB making machine

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.