- Production Machines

- Machine for the electronics industry

- Printed circuit board production machine

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

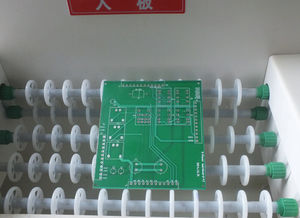

PCB production machine SUNY-ZHB400

Add to favorites

Compare this product

Description

SUNY-ZHB400

1. Usage: to achieve rapid PCB productions such as photographic plate imaging, etching, plated through hole, helping welding and preventing oxidation;

2. Product features: the process slots produced by transparent PVC material, heat resistance and anticorrosive, convenient for observing each technological process;

3. Process functions: imaging, etching, plated through hole, tin-plating, preventing oxidation, helping welding and characters;

4. Process slot configuration: every slot equipped with automatic stainless steel/titanium quality heating tube of constant temperature control (non-glass material, putting an end to the safety accidents like glass heated explosion) and self-contained liquid convection device;

5. Process characteristics: all liquid of process slot is environmental protection liquid, ensuring cleanness, no pollution and no bad smell of the environment;

6. The liquid and chemical raw materials pass the authentication of the national environmental authentication institution, including SGS report and CMA report; the waste water and gas emissions pass the emissions standards of the CMA authority environmental authentication, which can be directly discharged;

7. Control system: high-performance ARM embedded processor + embedded operating system, human-computer interface: big screen color LCD screen + touch screen;

8. Processing dimension: 220mm×320mm

9. Processing accuracy of circuit board: 0.1mm (4mil)

10. Through hole precision: 0.3mm

11. Heating tube: full sealed waterproof glass heating tube 300W/stick×5sticks;

12. Input power: AC220V/50Hz 1500W;

13. Overall dimension: 1000mm×450mm×680mm

14. Net weight: 40KG.

Catalogs

PCB making machine

156 Pages

Other U-Therm International (H.K.) Limited products

PCB making machine

Related Searches

- Marking machine

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- SMT pick-and-place system

- Printed circuit marking machine

- Automatic pick-and-place system

- Wave soldering machine

- PCB etching device

- Chemical PCB etching machine

- Automatic PCB etching machine

- Tinning machine

- PCB production machine

- Exposure system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.