- Industrial machines and equipment

- Printing, Marking and Engraving

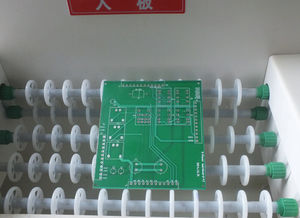

- PCB engraving machine

- U-Therm International (H.K.) Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PCB engraving machine SUNY-ZDK320millingautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- for PCB

- Other characteristics

- milling, automatic

Description

Specification:

1. Usage: automatic line carving, drilling and milling edge for circuit board;

2. Maximum working size: 320mm×320mm

3. Working mode: 2.5 d double-sided processing mode;

4. All module driving mode, three step motor modules + driving chip united to drive XYZ axis moving;

5. Casting fuselage, Y axis moves driving beam arm move, in sculpture and drilling process,

6. Random configuration of processing data auxiliary processing software, data directly into the machine without any external software;

7. With function of X, Y, Z axis hardware and software limit

8. High power spindle motor, higher processing precision, with memory function without electricity, no worries about outage;

9. Handle human-computer interface: 128 * 64 dot matrix liquid crystal display + 18 multi-function keys, with simple and intuitive operation;

10. Processing precision: ±0.05mm;

11. Repeat precision: 0.01mm;

12. Minimum processing line width: 4mil;Minimum line gap 6 mil above;

13. Suitable drilling flower: 0.3mm~3.175mm Drilling handle: 3.175mm;

14. Suitable milling cutter: 1mm~3mm Cutter handle: 3.175mm;

15. Processing speed: 0~3m/min(actual-time adjustable);

16. Spindle motor: 800W frequency conversion motor The highest speed 60000 revolves/min;

17. Step motor: 35W four phase step motor*3;

18. Shaft driving mode: entire advanceding screw driving

19. Spindle movements itinerary: 60mm;

20. With mating PC control software, lifetime free upgrades

21.Working power: AC220V/50Hz 1000W;

22. Overall dimension: main engine: 650mm×610mm×530mm;

control cabinet: 550mm×400mm×250mm;

23. Net weight: 105KG.

Catalogs

No catalogs are available for this product.

See all of U-Therm International (H.K.) Limited‘s catalogsOther U-Therm International (H.K.) Limited products

PCB making machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.