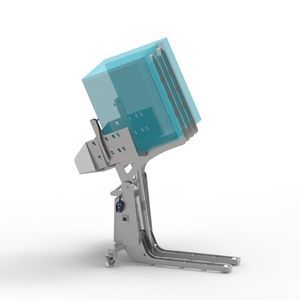

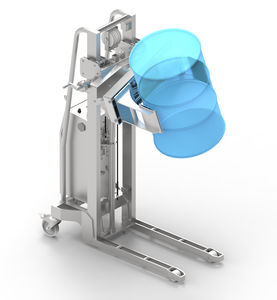

Electric tipping station EBT300D DRUM/BARRELdrumfor the food industrystainless steel

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Applications

- drum

- Other characteristics

- for the food industry, stainless steel, for the chemical industry

Description

Material: 100% Stainless Steel

ULMA Inoxtruck tilter allows an ergonomic handling/casting of loads, thanks to the tilting system 85˚ and 130˚. This equipment has an hygienic an ergonomic design for eurobines that make possible a dairy cleaning, avoiding the microbiological contamination risk and ergonomic load handling/tilting to conveyor belt or other containers, reducing the effort.

Hygienic and Innovative Design:

Totally opened chassis, waterproof compartment for lifting system and the operator drives and controls with IP protections provide together with continuous welding top hygienic design, making possible a total cleaning, keeping the equipment in perfect working order. Curved and sloped structure for a perfect drainage and a fast drying.

Ergonomics and Efficiency:

The ergonomic design of the handle and the existence of the emergency stop button and drive sides of the chassis to allow the operator to easily handle, reducing stress during transport and load dump. Furthermore, the funnel and tilting angle are adjustable, making possible to carry out different types of work with different types of eurobins. The automatic clamping for entry and remove the eurobin increases the ergonomy.

100% Stainless:

Manufactured 100% in stainless steel including all hydraulic equipment.

Minimum maintenance:

All bearings are sealed waterproof and self-lubricated. All moveable parts are supplied by free of lubrication polymeric bushings and the watertight batteries don´t need maintenance.

VIDEO

Catalogs

GENERAL CATALOGUE INOXTRUCK

32 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

20th Shanghai Heat treatment&Industrial Furnace Expo 2024

18-20 Dec 2024 Shanghai (China)

More information

Related Searches

- Metal trolley

- Pallet jack

- Stacker truck

- Electric stacker truck

- Handling trolley

- Walk-behind stacker truck

- Electric pallet jack

- Hand pallet jack

- Tipping station

- Materials handling stacker truck

- Transport pallet jack

- Stainless steel trolley

- Manual stacker truck

- Lifting stacker truck

- Scale pallet jack

- Tilter

- Stainless steel pallet truck

- Stand-up pallet truck

- Platform stacker truck

- Electric tipping station

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.