- Industrial machines and equipment

- Welding and Assembly

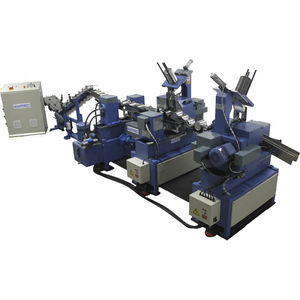

- Automatic assembly line

- Umar Makina Company

Automatic assembly line MAC/75706verticalrotaryhorizontal

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic, vertical, rotary, horizontal

- Applications

- for cans

Description

The can bodies are entered to the machine in vertical position.

This line consists of following stations:

1st Station: Inlet Conveyor and Synchronization to Body Transfer Arms

Infeed conveyor and synchronization to the transfer arms will move the can body between the stations for the below operations. Synchronization is performed by pneumatic fingers that are driven by electronic cam. Transferring arms’ back and forth and open-close movement is done by a cam system which is powered by servo motor.

2nd Station: Welding Line Indexing Unit

The body is turned on a rotary table in order to detect where the welding line is. The welding line is positioned as set on the screen. The detecting of the line is done via contrast sensor or ultrasonic sensor.

3rd Station: Body Shaping Unit (Expanding)

The cylindrical body is lifted up into the hanging expanding arms which will make the expanding from four corners. The expanding and the lifting with belt system is powered and controlled by servo motors. The expanding range and the lifting height can be adjusted from the touch display automatically.

4th Station: Bottom Flanging Unit

Mechanical powered flanging system is squeezing the body from corners. The expanded body is lifted to the upside down hanging flanging tool with servo cam mechanism.

The flanging and seaming heads are on the same column and head frame, for the set height adjustment they are moving together up and down.

5th Station: Bottom Seaming Unit with Automatic End Feeder

The ends are stacked on vertical conveyor in horizontal position and are fed automatically

VIDEO

Catalogs

No catalogs are available for this product.

See all of Umar Makina Company‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Resistance welding system

- Standalone welding system

- Spot welding system

- Pneumatic welding system

- Assembly line

- Automated assembly line

- Vertical welding system

- Semi-automatic assembly line

- Rotary assembly line

- Welding assembly line

- Vertical assembly line

- Horizontal assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.