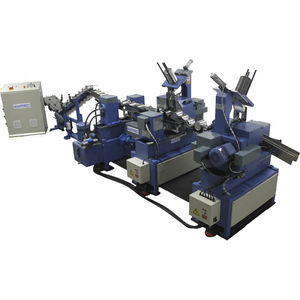

Automatic welding machine MAC/352pneumatic

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Other characteristics

- pneumatic

Description

The machine is designed for automatically aligning and welding of ear lugs on conical pails or round can bodies in single operation.

Place the body on the pneumatic stopper and depress the foot pedal. Automatically the operation will be started. The ear lugs for each side will be fed from the vibrators to the electrodes. The electrodes will clamp the body and start welding operation. After welding, the body will slide from the loading table and machine is ready for next operation. It is possible to weld ear lugs after ring seaming.

External water cooling system

Aligning/feeding of ear lugs by vibrator

Electronic welding control

Pre-heating before welding

Adjustable welding power and time

Welding of internally painted cans

Capacity - 30 cpm

Can Diameter (adjustable) - 160 - 300 mm

Transformer Power - 70 kVA

Supply Voltage - 220/380 Volt - 50/60 Hz

Air Consumption - 5 Bar 1.1 lt/operation

Approx. Machine Weight - 850 Kg

Machine Dimension - 1250 x 900 x 150 mm

Catalogs

No catalogs are available for this product.

See all of Umar Makina Company‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Resistance welding system

- Standalone welding system

- Pneumatic welding system

- Assembly line

- Spot welding system

- Automated assembly line

- Vertical welding system

- Semi-automatic assembly line

- Rotary assembly line

- Welding assembly line

- Vertical assembly line

- Horizontal assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.