- Production Machines

- Cutting Machine

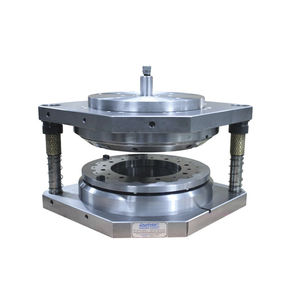

- Pneumatic press

- Umar Makina Company

Pneumatic press MAC/12522stampingcuttingdouble

Add to favorites

Compare this product

Characteristics

- Operation

- pneumatic

- Function

- stamping, cutting

- Structure

- double

- Control

- automatic

- Other characteristics

- vacuum

- Applications

- for thin metal strips

- Force

40 tf, 50 tf, 60 tf

- Rate (strokes/min)

60 p/min, 100 p/min, 120 p/min

- Stroke

Min.: 30 mm

(1.181 in)Max.: 130 mm

(5.118 in)- Max. pressure

6 bar

(87 psi)- Hydraulic pump power

6 kW, 8 kW

Description

Automatic strip feed press is designed to perform cutting and stamping of tin ends, lids, and rings. The strip is separated by vacuum suckers from the magazine and a pneumatic piston is pushing it to the feeding fingers. Strip feeding to the die is performed by double finger bar to have possibility using of double die. The feeding fingers are getting force from the crankshaft by chain. All linear movements on the strip feeding unit are guided by linear-bearing system.

Pneumatic operated disc clutch and spring brake system

Machine is developed to obtain maximum die life

Mechanical overload protection on the ram

Non-stop strips stacker system avoids stopping the machine while feeding the magazine

The PLC control system and the display provide easy use and follow all alarm messages

Central lubrication system controlled by PLC

Safety devices provide control of double strip feed, stuck in die area, stuck at skeleton strip eject area, low air pressure and operator safety guards

Catalogs

No catalogs are available for this product.

See all of Umar Makina Company‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.