- Food industry

- Fish Processing

- Salmon filleting machine

- Uni-Food Technic

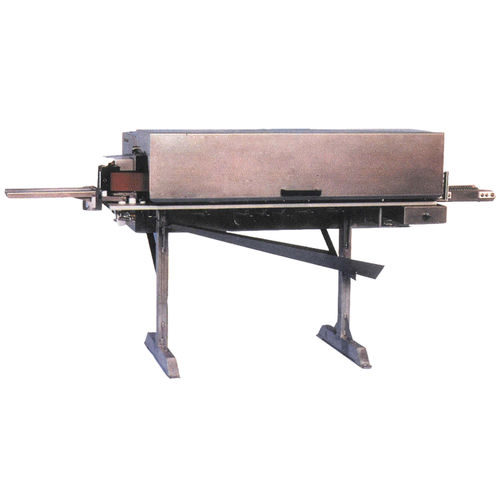

Trout filleting machine FR-150 & 200for salmonfor breamstainless steel

Add to favorites

Compare this product

Characteristics

- Type

- for trout, for salmon, for bream

- Other characteristics

- stainless steel

Description

Description

The Filleting Machines FR-150 & 200 are reliable, versatile, high speed filleting units specially designed for the production of single fillets free of back bone and ribs.

Only minor adjustments are required to process a wide variety of species and sizes due to the machines' unique location method that utilizes the internal bone structure of the fish.

METHOD OF OPERATION

An operator places the head-off fish onto the feed system between the feed rollers which carry the fish into the drive belts. In-feed systems for either eviscerated or non eviscerated fish are available.

The drive belts then transport the fish over the belly cutting blades and belly cleaning wheel and past the back bone removal blades.

The back bone and offal are ejected into the waste chute and the two separate halves of the fish are located onto rib guides for transportation past the rib removal blades.

The rib is then removed and ejected into the waste chute, and the two fillets are placed skin-down onto a discharge conveyor.

The FR-150 is specially designed to accommodate fish in the size of 85-450 g, such as lake perch, bass, trout, bream and garfish.

The FR-200 is suitable for a variety of fish in the size range of 340-1800 g, including trout, ocean perch, lake perch, redfish, whitefish, walleye, tilapia, mullet, salmon, mackerel, bass, sea bass and sea bream.

Catalogs

No catalogs are available for this product.

See all of Uni-Food Technic‘s catalogsRelated Searches

- Slicer

- Automatic slicer

- Floor-standing slicer

- Fish slicer

- Fish skinning machine

- Automatic fish skinning machine

- Fish scaling machine

- Salting machine

- Heading machine

- Pinbone remover

- Salmon fish skinning machine

- Gutting machine

- Fish gutting machine

- Automatic fish scaling machine

- Filleting machine

- Salmon pinbone remover

- Fish filleting machine

- Fish heading machine

- Trout pinbone remover

- Fish processing line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.