- Food industry

- Fruit and Vegetable Processing

- Vegetable processing line

- Uni-Masz H.M. Juszczuk Sp.j.

Mushroom processing line

Add to favorites

Compare this product

Characteristics

- Food product

- for mushrooms

Description

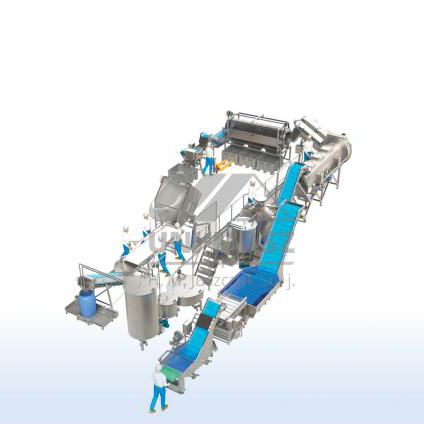

PROCESSING CHAMPIGNONS - MUSHROOMS

WASHERS – Used for initial washing with air support. Initial washing in water closed circle, final cleaning with fresh water sprinklers. Unit is equipped with pump, slotted sieve and air turbine.

DRUM CALIBRATOR – Used to separating product on fractions, calibrating champignons using sieve with round shaped holes. Sieve shape and hole size are set depending on processed product and client needs.

INSPECTION TRANSPORTER-Used to manual sort champignons before moving them to cutter.

BRUSH WASHER – Used for exact cleaning from cemented peat.

CHAMPIGNON CUTTER - -Used to cut mushrooms in slices (thickness 4-8mm). Cutting using round knifes – dry method.

VACUUM CHAMBER – Used to structural saturate mushrooms with water or solution. Level can be regulated up to 60%. Capacity (3-4) cycles/h.

WASHER-SOAKER + HOPPER FOR CRATES/PALLETES

Charging product to washer by hopper. Washer-soaker besides washing can be used for any mushroom soaking in solution in batch with air section as well as with spades that are pushing product forward. The process goal is to unify the mushroom’s structure.

SCREW BLANCHER – Used for blanching cut or whole mushrooms.

Catalogs

No catalogs are available for this product.

See all of Uni-Masz H.M. Juszczuk Sp.j.‘s catalogsOther Uni-Masz H.M. Juszczuk Sp.j. products

TECHNOLOGICAL LINES

Related Searches

- Slicer

- Automatic slicer

- Food washing tunnel

- Vegetable food cleaning machine

- Fruit food cleaning machine

- Fruits and vegetable slicing machine

- Automatic food washing tunnel

- Belt food cleaning machine

- Drum food cleaning machine

- Rinsing food washing tunnel

- Brush food washing tunnel

- Vegetable processing line

- Vibrating food cleaning machine

- Peeler-washer-scrubber

- Air-water food washing machine

- Cucumber washing machine

- Fan food cleaning machine

- Fruit pulper

- Pulper

- Vegetable washing line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.