- Food industry

- Fruit and Vegetable Processing

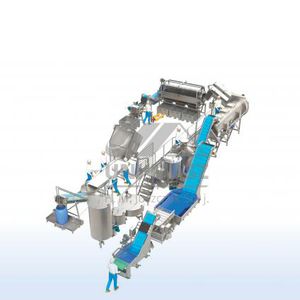

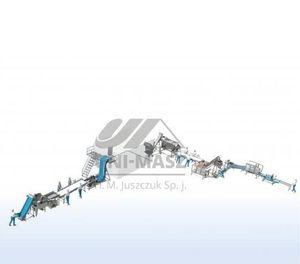

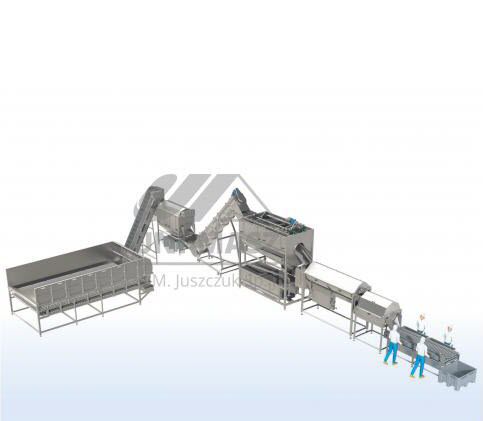

- Vegetable washing line

- Uni-Masz H.M. Juszczuk Sp.j.

Vegetable washing line

Add to favorites

Compare this product

Characteristics

- Function

- washing

Description

Vegetables are charged manually from the bags to the charge basket CHARGING ELEVATOR on rotating, rubber stars STAR DE-GROUNDER where soil and light impurities (also small 20mm vegetables) are falling down to the container. Afterwords product is being dry cleaned on the roller brushes BRUSH CLEANER. Soil and impurities are falling down through the brushes. Underneath the cleaner and de-grounder there is placed container for impurities. Initially the cleaned product is calibrated on the ROLLER CALIBRATING MACHINE with the infinitely variable adjustment one the roller gap. Good product is falling down between roller gaps into WASHER CHARGE TRANSPORTER basket (oversized product is being moved outside on rollers to another container). In DRUM WASHER product is immersed in water, mixed with spades and moved forward into the washer output direction to fall down directly to CORUNDUM PEELER peeling chamber. On the strength of rough corundum rollers product is peeled and moved by screw band under light water shower (peeled impurities are taken out by the screw transporter and pushed through the slotted sieve). Extruded water is going to the rotating drum filter, extruded peelings are removed outside the unit. After the peeling product is being swilled out from scum and light impurities in DRUM CLEANER under fresh water shower.

Catalogs

No catalogs are available for this product.

See all of Uni-Masz H.M. Juszczuk Sp.j.‘s catalogsOther Uni-Masz H.M. Juszczuk Sp.j. products

TECHNOLOGICAL LINES

Related Searches

- Slicer

- Automatic slicer

- Food washing tunnel

- Vegetable food cleaning machine

- Fruit food cleaning machine

- Fruits and vegetable slicing machine

- Automatic food washing tunnel

- Belt food cleaning machine

- Drum food cleaning machine

- Rinsing food washing tunnel

- Brush food cleaning machine

- Vegetable processing line

- Vibrating food cleaning machine

- Peeler-washer-scrubber

- Air-water food washing machine

- Cucumber washing machine

- Fan food cleaning machine

- Fruit pulper

- Pulper

- Bell pepper washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.