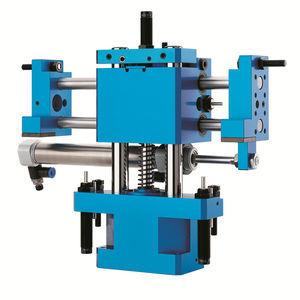

Pneumatic manipulator BP seriesvacuumpositioningtransport

Add to favorites

Compare this product

Characteristics

- Drive type

- pneumatic

- Gripping device

- vacuum

- Applications

- positioning, transport

- Other characteristics

- rotary, pick-and-place

- Domain

- optical industry, for the toy industry, for the electronics industry, for watchmaking, for the eyewear sector, for the electromechanical sector, for packaging machines

- Maximale stroke

Max.: 100 mm

(4 in)Min.: 0 mm

(0 in)- Pressure

Max.: 6 bar

(87 psi)Min.: 3 bar

(43.5 psi)- Rotation

Max.: 180 °

Min.: 0 °

Description

With their high speed, precision and repeatability, Unimec rotary manipulators can be used for numerous applications in the transport and assembly of parts in fields such as electronics, micromechanics, mechanics, watchmaking, spectacles and optical instruments, toys, optics, equipment, and in the areas of conditioning processing and positioning.

Picking up and setting down positions as well as movement speeds are adjustable independently. These rotary manipulators have hydraulic shock absorbers at the end of the rotation. They also have carbide travel stops.

Two dimensions are available: BP66 and BP100

Rotating arms BP66

BP66: 2 positions, for picking up and setting down

BP1663: 3 positions, for picking up and setting down with intermediate stop

Rotating arms BP100

BP100: 2 positions, for picking up and setting down

BP103: 3 positions, for picking up and setting down with intermediate stop

Features

- Transport and assembly of different parts

- High speed and precision

- Repeatability of sequences

- Numerous application possibilities

- Independently adjustable picking up and setting down positions

- Independently adjustable movement speeds

- Hydraulic shock absorbers at the end of the rotation

- Carbide travel stops

VIDEO

Catalogs

Related Searches

- Pneumatic manipulator arm

- Manipulator arm with gripping tool

- Positioning manipulator arm

- Electric manipulator arm

- Vacuum manipulator arm

- Rotary manipulator arm

- Transport manipulator arm

- Compact manipulator

- Linear array manipulator

- Electronic manipulator arm

- Packaging machine manipulator arm

- Manipulator for the electronics industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.