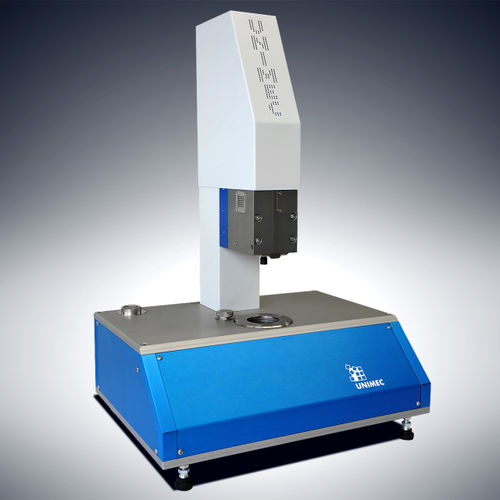

This device enables measure and ageing on torques in rotation. Used in the watchmaking industry, it enables measure of barrels, crowns, frictions, etc. With its torque and force sensors, this equipment allows reliable and combined measures.

The measure head is interchangeable. Several units are available according to desired precision and measure range. The measure quality is guaranteed by a torque sensor and an electronic design especially developed for this device. Aerostatic bearings ensure a rotation without friction and compensate alignment errors of the measured element.

Variants:

Version with 1 measuring head

• Manual Z-axis

• Motorized Z-axis: possibility of automatic engagement and control of axial constraint

Version with 5 measuring heads

• Manual Z-axis

• Motorized Z-axis: possibility of automatic engagement and control of axial constraint

Options

Motorized Z-axis

Software extension for measure on barrels

Equipment

• This device enables measure and ageing on torques in rotation. The force and torque sensors enable measures of barrels, crowns, frictions, etc. This equipment allows reliable and combined measures.. Aerostatic bearings ensure a rotation without friction and compensate alignment errors of the measured element. The two motorizations version allows automatic engagement of the piece and measurement under constraint.

Torque measure

• The torque sensor has especially been desiged for this equipment's needs. It uses a contactless communication technology.

Force measure

• The flat bearing is associated with a force sensor. This sensor enables to measure constraint applied on the piece by deplacement of the Z-axis.