- Products

- Winding device

- UNIMEC

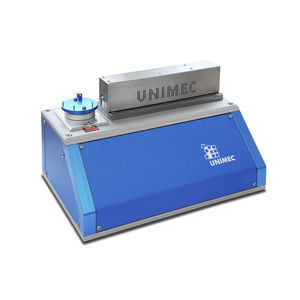

Automatic winding device for watchmaking

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for watchmaking

Description

This device allows the automatic winding of watches or movements in series by way of the crown. All the watches (10 maximum) are placed on a rotary table. The plate is adjustable to each form of case or movement. An automatic recognition allows to attribute parameters to the plate. It is possible to have up to 31 different programmed pates.

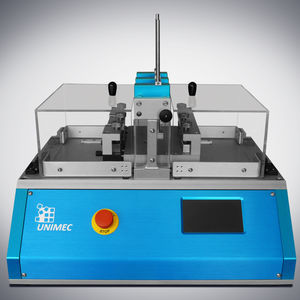

Rotation speed, rotations number and torque limits of the crown can be configured, which enables this device to be adapted to your mechanisms at best. With the coupling system, the crown is pressed correctly, without any risk of damage.

Equipment

• This device allows the automatic winding of watches or movements in series by way of the crown. All the watches (10 maximum) are placed on a rotary table. The plate is adjustable to each form of case or movement.

Load detection

• The end of the winding can be programmed in two different ways: by the overrun of a given torque, or after a certain given number of rotations. In any case, the winding is protected by a torque threshold which can be configured.

Adjustable parameters

The rotation speed, the rotations number and the torque limits of the crown can be

configured, which enables this device to be adapted to your mechanisms at best.

Coupling of the crown

• A toothed wheel on the side allows to adjust the position of the chuck. In this way,

the crown is pressed correctly, without any risk of damage. The function is realised by

friction between a specific tool (interchangable) and the crown.

VIDEO

Catalogs

No catalogs are available for this product.

See all of UNIMEC‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.