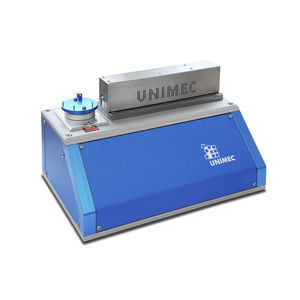

Accelerated aging testing system FermoirTestwatchbenchtopmotorized

Add to favorites

Compare this product

Characteristics

- Test type

- accelerated aging

- Tested product

- watch

- Configuration

- benchtop

- Other characteristics

- motorized, pneumatic

Description

This equipment is dedicated to ageing and measuring of watchstrap clasp. With its conception and its micrometric adjustment, this device can be adapted precisely and qucikly to all main existing types of clasp.

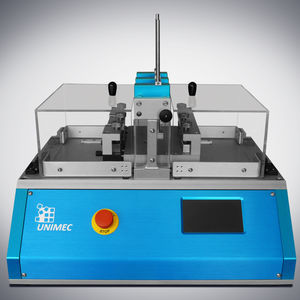

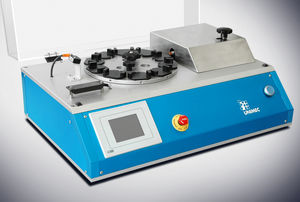

The clasp is fixed flat on the machine. Opening is made by three pneumatic actuators: two actuators trigger lateral buttons, then an actuator opens the clasp.

Clasp closing is made by a motorised measuring head that integrates a force sensor and that enables to measure the force and position of closing. Evolution of force/position can be observed with statistical charts. This measuring head is vertically assembled on the equipment. Maximum limits can be defined. This equipment also enables to measure lateral buttons in the same way as clasp closing.

Clasp is fixed on a special support printed in 3D. This conception allows the user to quickly develop its own supports.

It is possible to programme the cycle differently according to tested parts. Approach position, cycles number, cycle time and actuator travel are programmable. This equipment enables to save programs as well as different clasp types. It is also possible to save and extract the results of carried out tests.

Equipment

• This equipment is dedicated to ageing and measuring of watchstrap clasp. With its conception and its micrometric adjustment, this device can be adapted precisely and quickly to all main existing types of clasp.

Principle

• The clasp is fixed flat on the machine. Opening is made by three pneumatic actuators: two actuators trigger lateral buttons, then an actuator opens the clasp.

Catalogs

No catalogs are available for this product.

See all of UNIMEC‘s catalogsRelated Searches

- Measuring machine

- Test stand

- Automatic measuring machine

- Manual test kit

- PC-controllable test bench

- Test set

- Manual test stand

- Benchtop testing system

- Control measuring machine

- Vertical test stand

- Tabletop testing device

- Laboratory measuring machine

- Material test bench

- Laboratory test equipment

- Pneumatic test stand

- Resistance test equipment

- Laboratory test stand

- PC-controllable testing device

- Material test equipment

- Direct-contact measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.