Material preparation station mta®dispensingfor self-leveling mediapolymer

Add to favorites

Compare this product

Characteristics

- Associated function

- dispensing

- Applications

- for materials, polymer, for self-leveling media

- Other characteristics

- automatic, custom

Description

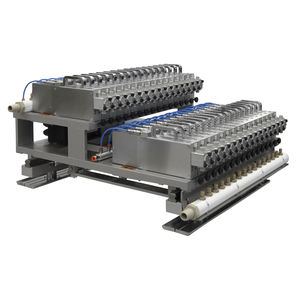

Whether working with polyurethanes, epoxy resins, silicones, greases or other fluids, it is often necessary to prepare the materials before processing. This is due to issues such as sedimentation, air bubbles or dissolved air in the material. With its extensive experience in dispensing processes and automation, Unitechnologies provides appropriate technical solutions for the entire process, from preparation to volumetric dispensing of the material.

To remove air from the material, degassing is carried out by applying a vacuum. Pressurizing the degassed material would be counterproductive, as it would result in air inclusions or, as with silicones, to air saturation. Therefore, the mta CFD continuous flow dispenser, which is based on progressive cavity pump, is used to gently convey the material by mechanical movement from the supply tank. In addition, the pump is also used to recirculate the material via a bypass line after longer shutdowns, without vacuum application, to prevent processing problems.

For filled materials, it is necessary to homogenize the material while simultaneously removing air bubbles. mta’s systems are specifically designed to facilitate the parallel mixing and degassing of the material. The combination of these two processes guarantees a homogeneous, bubble-free material.

Furthermore, mta’s modular and flexible systems offer several supply options for conveying low to high viscosity material, including filled materials, from the tank to either the CFD or NVD dispensers of mta's range.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.