- Metrology - Laboratory

- Metrology and Test Equipment

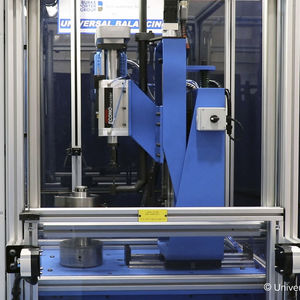

- Horizontal balancing machine

- Universal Balancing

- Products

- Catalogs

- News & Trends

- Exhibitions

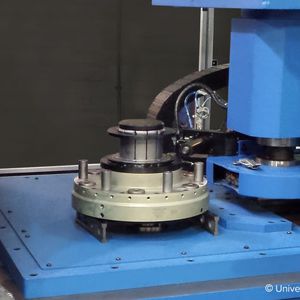

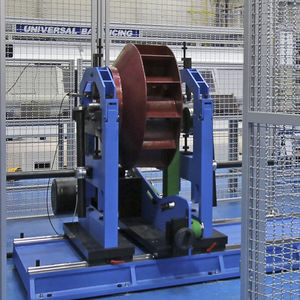

Rotor balancing machine horizontaldynamicautomatic

Add to favorites

Compare this product

Characteristics

- Orientation

- horizontal

- Type

- dynamic

- Applications

- for rotors

- Other characteristics

- automatic, high-accuracy

Description

eRotor Balancers eMobility

Automatic single or multi-station eRotor balancing machines designed for high and medium volume production lines.

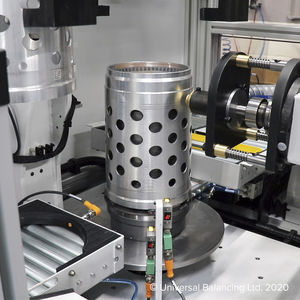

Manual single station eRotor balancing machines designed for low production and R&D facilities.

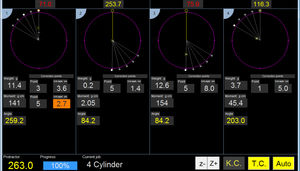

Ultra-high accuracy and repeatability of <10% part tolerance.

Industry leading cycle time.

Summary

We supply eRotor balancing machines that deliver ultra-high accuracy and repeatability, exceeding the electric vehicle industries process capability demands.

Single and multi-station variants are available for high, medium and low volume production lines, as well as R&D facilities.

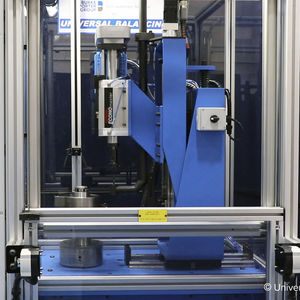

Our high-volume eRotor balancing machines are offered as complete cells or as standalone systems to go into customer cells, both are typically integrated by robot or pick and place gantry.

Machines are supplied with integrated automatic or manual correction, or as audit only stations. Drilling is the primary unbalance correction method, but other methods such as mill, weight addition and special proprietary technologies are available to meet your exact requirements.

Our eRotor balancing machines come with our industry leading UNI-64 Windows measuring system and easy to use Winbal balancing software. This includes error proofing of setups and operation, and hosts features to improve cycle time, prompt routine maintenance checks and comprehensive industry 4.0 in-built diagnostics functionality.

All our machines have a small footprint as standard, are installed and commissioned in as little as 2 days and are built largely with industry standard components.

Related Searches

- Balancing system

- Dynamic balancing system

- Horizontal balancer

- Vertical balancer

- Automatic balancing system

- Rotor balancer

- High-accuracy balancer

- Fan balancer

- Universal balancer

- Compact balancing machine

- Static balancing system

- Shaft balancer

- Brake disc balancer

- Semi-automatic balancing machine

- Balancing machine for automotive applications

- Pulley balancing machine

- Turbine wheel balancing system

- Pump balancer

- Manual balancing machine

- Flywheel balancing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.