- Metrology - Laboratory

- Metrology and Test Equipment

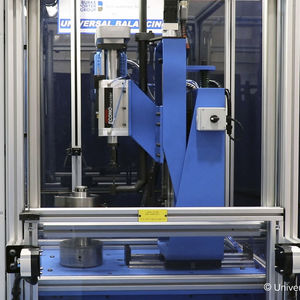

- Crankshaft balancing machine

- Universal Balancing

- Products

- Catalogs

- News & Trends

- Exhibitions

Crankshaft balancer automaticsemi-automatic

Add to favorites

Compare this product

Characteristics

- Applications

- for crankshafts

- Other characteristics

- automatic, semi-automatic

Description

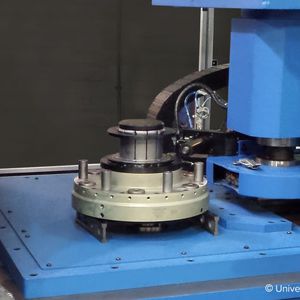

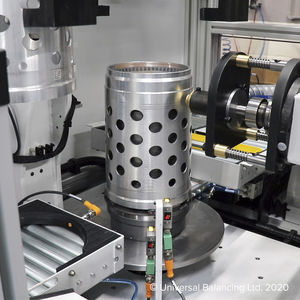

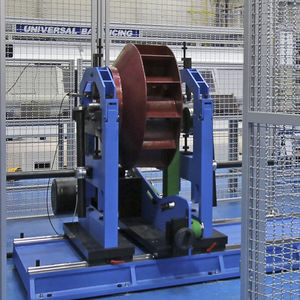

CRANKSHAFT BALANCERS

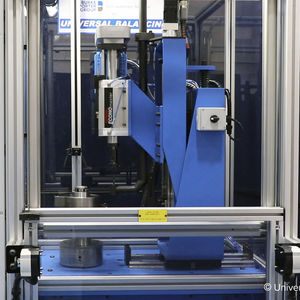

Universal Balancing’s crankshaft balancing machines are designed for high production environments offering rapid part to part cycle time, high levels of reduction ratio – all in a small footprint. The machines can be in conjunction with automated or manual work handling systems.

OVERVIEW

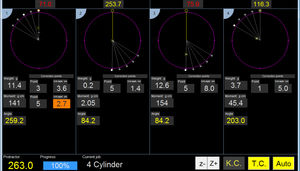

Our crankshaft balancers are specifically designed for fast and accurate measurements, all while ensuring a small footprint. They’re simple to install and even easier to use, with a single HMI point of access to the machine for effortless maintenance. The UNI-64 Windows based measuring system and Winbal balancing software has a self-teaching algorithm which corrects unbalance with the smallest number of drills holes across all possible pins.

PRODUCT FEATURES

• Full-auto or semi-auto balancers

• Support 3, 4, i6, v6, v8, and v10 cylinder cranks

• Single station standalone or rotary stations

• Maximum flexibility—wide range of cranks

• High-powered vacuum extraction

Related Searches

- Balancing system

- Dynamic balancing system

- Horizontal balancer

- Vertical balancer

- Automatic balancing system

- Rotor balancer

- High-accuracy balancer

- Fan balancer

- Universal balancer

- Compact balancing machine

- Static balancing system

- Shaft balancer

- Brake disc balancer

- Semi-automatic balancing machine

- Balancing machine for automotive applications

- Pulley balancing machine

- Turbine wheel balancing system

- Pump balancer

- Manual balancing machine

- Flywheel balancing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.