Conveyor accumulating table BUFFERSEP

Add to favorites

Compare this product

Characteristics

- Options

- for conveyor

Description

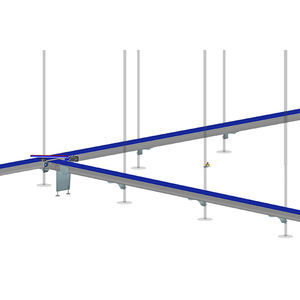

It is an automated buffer table for degrouping and distributing pots and trays into individual units.

The BUFFERSEP is a very useful machine for carrying out of the intermediate stages of the production process better and faster: with a transport fork, the containers can be positioned directly on the feeding buffer belt where a specially designed bar system will identify the rows and will advance them one at a time on the intermediate belt.

From here, in an automated manner, the pots will proceed neatly as single units on the output belt, where they can be easily reached to be processed directly by the operator or to be sent to the next phase.

The machine is completely customisable according to the customer’s requirements and offers considerable savings in terms of labour and time and, consequently, a greater production yield.

TECHNICAL SPECIFICATIONS - BUFFERSEP

• Feeding belt, complete with three-bar separation unit, L = 6000×1920 mm.

• Accumulation belt, L = 2400×500 mm.

• Exit belt, L = 1300×500 mm.

• Machine controlled by PLC: control panel with touch-screen monitor.

• Fencing safety guards with access doors.

• Pots belt exit speed adjustable by frequency drive.

• Belts and take off three-bars device motion electronically controlled with encoder for position.

• Radio remote control with start/stop on pots loading phase.

• Available in left and right version.

DETAILS / MAIN ACCESSORIES - BUFFERSEP

• Feeding belt length: up to 12000 mm.

• Feeding belt width: up to 3000 mm.

• Wheels kit, to facilitate the machine positioning.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Urbinati S.R.L.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.