- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

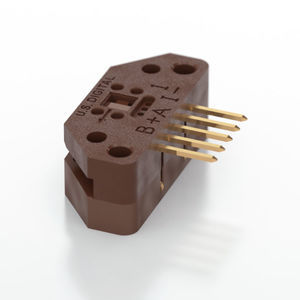

Incremental rotary encoder EC35opticalshaft-mountedcommutation

Add to favorites

Compare this product

Characteristics

- Type

- incremental

- Technology

- optical

- Construction

- shaft-mounted

- Output signal

- commutation

- Applications

- for OEM

Description

The EC35 quick assembly optical commutation encoder is designed for high volume, low cost, OEM motion control applications. The EC35 provides A/B/Z incremental outputs and U/V/W outputs for brushless motor commutation.

The EC35 mounts to the motor using 2 screws on a 1.28" or 1.812" diameter bolt circle. The precision machined encoder hubdisk pushes on when the encoder assembly is put on the motor shaft. This design securely grips the shaft without set screws. A built in, removable spacer tool ensures that the encoder disk is automatically set to the correct gap when the encoder housing is mounted. The encoder can be "timed" by rotating a ring on the assembly and pressing the ring in with a simple tool to lock everything into place.

The EC35 is powered by a single 5V supply and comes with a 15-pin connector that provides differential outputs for A/B/Z and U/V/W. Open-collector U/V/W outputs are available as an option. Single ended output can be obtained by only using the + outputs of each differential pair. The internal 26C31 line drivers can source and sink 20 mA at TTL levels. The recommended differential receiver is the industry standard 26C32. Maximum noise immunity is achieved when the differential receiver is terminated with a 150 Ω resistor in series with a .0047 μF capacitor placed across each differential pair.

VIDEO

Catalogs

Related Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Tilt sensor

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- IP65 rotary encoder

- Aluminum rotary encoder

- DC rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Digital tilt sensor

- Multi-turn rotary encoder

- Robust rotary encoder

- Analog tilt sensor

- 5 VDC rotary encoder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.