- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

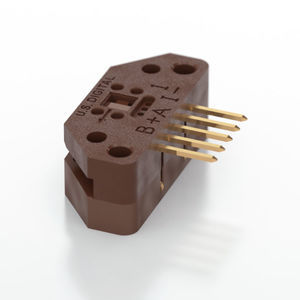

Incremental rotary encoder S2 opticalsolid-shaftnon-contact

Add to favorites

Compare this product

Characteristics

- Type

- incremental

- Technology

- optical

- Construction

- solid-shaft, non-contact

- Output signal

- digital output, Line Driver

- Supply voltage

- 5 VDC

- Protection level

- standard

- Other characteristics

- high-resolution, miniature, 2-channel

- Incremental encoder résolution (pulses per revolution

Max.: 40,000 unit

Min.: 256 unit

- Rotational speed

Max.: 10,000 rpm

(62,832 rad.min-1)Min.: 100 rpm

(628 rad.min-1)- Process temperature

Max.: 100 °C

(212 °F)Min.: -40 °C

(-40 °F)

Description

2-channel quadrature, TTL square wave outputs

3rd channel index option

Wide operating temperature

Product Description

The S2 series high resolution optical shaft encoder is a non-contacting rotary to digital converter. Useful for position feedback or manual interface, the encoder converts real-time shaft angle, speed, and direction into TTL-compatible quadrature outputs with or without index. It operates from a single .

The S2 is our first generation ball-bearing optical shaft encoder and is available for those customers who have designed it into their products; however, the S6 is recommended for new designs in place of the S2.

The S2 is designed to drive cables up to 10 feet long. For longer cable lengths, adding a PC4/PC5 differential line driver is recommended.

Three shaft torque versions are available:

The default torque version has a sleeve bushing designed to provide torque and feel ideal for front panel human interface applications.

The ball-bearing version uses miniature precision ball bearings that are suitable for high-speed and ultra-low torque applications.

The light static drag option has a sleeve bushing that does not intentionally add torque for low RPM applications where a small amount of torque is acceptable.

Connection to the S2 series encoder is made through a 5-pin standard connector. The mating connectors are available from US Digital with several cable options and lengths.

Related Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Tilt sensor

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- IP65 rotary encoder

- DC rotary encoder

- Aluminum rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Digital tilt sensor

- Multi-turn rotary encoder

- Robust rotary encoder

- 5 VDC rotary encoder

- Analog tilt sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.