- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Incremental rotary encoder E3opticalmechanicaldigital

Add to favorites

Compare this product

Characteristics

- Type

- incremental

- Technology

- optical, mechanical

- Output signal

- digital, Line Driver

- Supply voltage

- 5 VDC

- Material

- aluminum

- Protection level

- rugged, standard, rugged

- Other characteristics

- high-resolution, flat

- Incremental encoder résolution (pulses per revolution

Max.: 40,000 unit

Min.: 256 unit

- Rotational speed

60,000 rpm

(376,991 rad.min-1)- Output frequency

300 kHz

- Process temperature

Max.: 100 °C

(212 °F)Min.: -40 °C

(-40 °F)

Description

Quick, simple assembly, and disassembly

Rugged screw-together housing

Accepts .010 in. axial shaft play

Small size

2 channel quadrature TTL squarewave outputs

Optional index (3rd channel)

Product Description

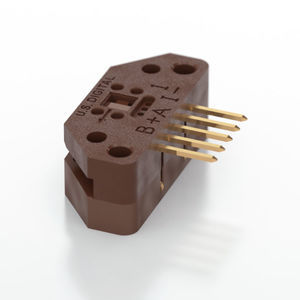

The E3 is a high-resolution rotary encoder with a rugged glass-filled polymer enclosure, which utilizes either a 5-pin locking or standard connector. This optical incremental encoder is designed to easily mount to and dismount from an existing shaft to provide digital feedback information.

The internal components consist of a mylar disk mounted to a precision machined aluminum hub and an encoder module. The hub is available for diameters up to 1 in. The module contains a highly collimated solid-state light source and monolithic phased array sensor, which together provide a system extremely tolerant to mechanical misalignments.

The E3 is normally designed for applications of 10 feet or less. For longer cable lengths, adding a PC4 / PC5 differential line driver is recommended.

Attachment of the base to a surface may be accomplished by utilizing one of several machine screw bolt circle options. Positioning of the base to the centerline of a shaft is ensured by use of a centering tool. The cover is securely attached to the base with two 4-40 flat head screws to provide a resilient package protecting the internal components.

Connection to the E3 product is made through either a 5-pin locking or standard connector. The mating connectors are available from US Digital with several cable options and lengths.

Catalogs

Related Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Tilt sensor

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- IP65 rotary encoder

- Aluminum rotary encoder

- DC rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Digital tilt sensor

- Multi-turn rotary encoder

- Robust rotary encoder

- Analog tilt sensor

- 5 VDC rotary encoder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.