- Production Machines

- Plastics Processing

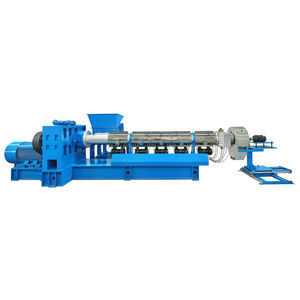

- Parallel twin-screw extruder

- USEON Technology Limited

Parallel twin-screw extruder SAT seriesco-rotating twin-screwflexible

Add to favorites

Compare this product

Characteristics

- Number of screws

- co-rotating twin-screw, parallel twin-screw

- Other characteristics

- flexible

- Output

Min.: 150 kg/h

(330.6934 lb/h)Max.: 3,500 kg/h

(7,716.1792 lb/h)- Screw diameter

Min.: 41 mm

(1.6 in)Max.: 135 mm

(5.3 in)- Maximum speed

400 rpm, 600 rpm, 800 rpm

(2,513 rad.min-1, 3,770 rad.min-1, 5,027 rad.min-1)- Torque

4,456 Nm

(3,287 ft.lb)- Power

Min.: 75 kW

(101.97 hp)Max.: 1,000 kW

(1,359.62 hp)

Description

With 10.3Nm/cm3 specific torque, this extruder is able to perform more delicate processing tasks, precise process controls to fulfill intricate and sophisticate processing purpose. Better dispersion, more accurate temperature controls and higher throughput have been integrated and optimized further.

Our SAT Series, Co-rotating Twin Screw Extruder, is our most popular twin screw extruder. It is multifunctional. With a more powerful gearbox and more precise screw elements, this extruder has a more flexible processing range and wider operation window. We also provide individual solution according to customized requirements. With a variety of modular screw elements, barrels, melt filtration and pelletizing system, we will promise you a worthy investment.

The perfect concept of the split-transmitting principle has been successfully applied in USEON-patented gearbox with the digital online monitoring system; each gearbox is assembled with precise positioning for torque balance.

A parallel co-rotating twin-screw extruder is an extruder in which the two screws are parallel and rotate in the same direction.

Co-rotating twin-screw extrusion technology first originated in the 1860s. After years of development, there are now many companies that can produce such extruders.

Among them, Coperion, JSW, Kobelco, DXS and USEON are the only five in the world that have made twin-screw extruders with screw diameters above 250mm.

* DXS = Dalian Rubber & Plastics Machinery Co., Ltd

Our SAT75 gearbox can install maximum 280kW with screw speed 600rpm.

Total Torque of the gearbox=9550x280KW/600rpm=4456N.m

The center distance between two output shaft (D) is 6cm

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other USEON Technology Limited products

Compounding Extrusion

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Plastic sheet extrusion line

- Twin-screw screw extruder

- Polypropylen extrusion line

- Multilayer extrusion line

- Plastic pelletizer

- Polyethylene extrusion line

- Single-screw screw extruder

- Compounding screw extruder

- Extrusion line with water cooling

- PP screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- PVC screw extruder

- Single layer extrusion line

- Laboratory screw extruder

- PE screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.