- Production Machines

- Plastics Processing

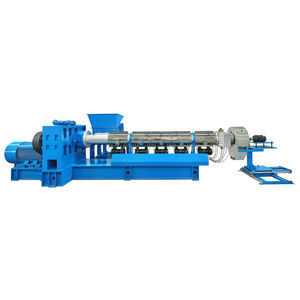

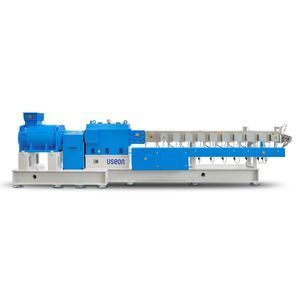

- Compounding extruder

- USEON Technology Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Compounding extruder SAT65for PLAfor biodegradable thermoplasticsparallel twin-screw

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for PLA, for biodegradable thermoplastics

- Number of screws

- co-rotating twin-screw, parallel twin-screw

- Other characteristics

- for masterbatch, flexible, vented

- Output

Max.: 900 kg/h

(1,984.1604 lb/h)Min.: 500 kg/h

(1,102.3113 lb/h)- Screw diameter

62.4 mm

(2.5 in)- Maximum speed

800 rpm

(5,027 rad.min-1)- Torque

4,456 Nm

(3,287 ft.lb)- Power

220 kW

(299.12 hp)

Description

With 10.3Nm/cm3 specific torque, this extruder is able to perform more delicate processing tasks, precise process controls to fulfill intricate and sophisticate processing purpose. Better dispersion, more accurate temperature controls and higher throughput have been integrated and optimized further.

Our SAT Series, Co-rotating Twin Screw Extruder, is our most popular twin screw extruder. It is multifunctional. With a more powerful gearbox and more precise screw elements, this extruder has a more flexible processing range and wider operation window. We also provide individual solution according to customized requirements. With a variety of modular screw elements, barrels, melt filtration and pelletizing system, we will promise you a worthy investment.

The perfect concept of the split-transmitting principle has been successfully applied in USEON-patented gearbox with the digital online monitoring system; each gearbox is assembled with precise positioning for torque balance.

Instead of using traditional casting heaters (outside the barrel), we use cartridge heaters, which are made in Germany and are inside the barrel. This will save energy, and the polymer will melt mostly by heating, not kneading elements. So, the shelf life of screws and barrels are longer, and the quality of compounding is better.

We supply Twin Screw Extruder For Biodegrade Plastic Compounding for PLA/PE filling with (cassava/corn/potato)starch, PBS degassing, PLA/PBS alloy and so on. These are manufactured as per the industrial standards and are provided to the clients in customized specifications as per their requirements.

VIDEO

Catalogs

Other USEON Technology Limited products

Extruder & Compounding Machines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Plastic sheet extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- ABS screw extruder

- PVC screw extruder

- Single layer extrusion line

- Laboratory screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.