- Production Machines

- Plastics Processing

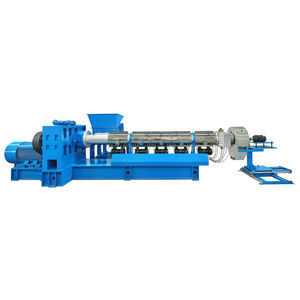

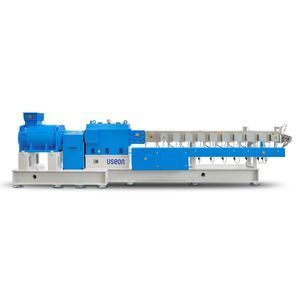

- Compounding extruder

- USEON Technology Limited

Compounding extruder U seriestwin-screw

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Number of screws

- twin-screw

- Screw diameter

Max.: 93 mm

(3.7 in)Min.: 27 mm

(1.1 in)- Maximum speed

900 rpm, 1,000 rpm, 1,200 rpm

(5,655 rad.min-1, 6,283 rad.min-1, 7,540 rad.min-1)- Torque

Max.: 7,110 Nm

(5,244 ft.lb)Min.: 145 Nm

(107 ft.lb)- Power

Max.: 1,350 kW

(1,835.49 hp)Min.: 37 kW

(50.31 hp)

Description

U series twin screw extruder is the highest-level series of USEON, mainly specialized for products with high speed and high torque, such as engineering plastics, masterbatch and other applications; specially designed for small and medium-sized blending modification production and application, easier to install and debugging, achieving high productivity.

U series twin screw extruder models ranging from LAB models to capacity of about 2t/h, basically cover entire range of small and medium-scale compounding applications, providing users maximum flexibility in different specifications and models, and scale-up.

Design of 15 Nm/cm3 and 1000R levels 30% higher than previous generation, with increased output by more than 50%, ensuring product quality and economic returns.

New processing section design and large number of materials configuration scheme provide with high temperature control accuracy and longer service life

High torque: torque of 15 Nm/cm3, meeting higher filling rate and production capacity, greatly improving productivity with reduced specific energy input;

High speed: maximum screw speed up to 1000r, configured screw speed and motor based on process. Screw speed of some models available up to 1200r;

High efficiency: increased temperature control accuracy and efficiency of the processing section by optimized heating and cooling system. Each barrel is distributed with 4-6 radial U-shaped (U-Cooling) cooling channels along the axial length, replacing the previous industry-wide axial reciprocating cooling channels, improving cooling efficiency and reducing radial deformation.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other USEON Technology Limited products

Compounding Extrusion

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Plastic sheet extrusion line

- Twin-screw screw extruder

- Polypropylen extrusion line

- Multilayer extrusion line

- Plastic pelletizer

- Polyethylene extrusion line

- Single-screw screw extruder

- Compounding screw extruder

- Extrusion line with water cooling

- PP screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- PVC screw extruder

- Single layer extrusion line

- Laboratory screw extruder

- PE screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.