- Production Machines

- Plastics Processing

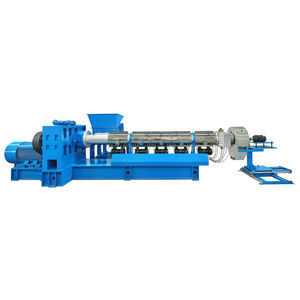

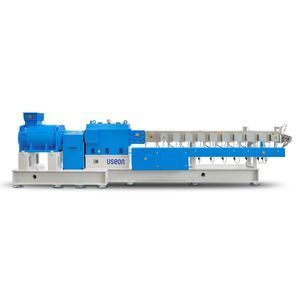

- Compounding extruder

- USEON Technology Limited

Compounding extruder TDY seriesfor WPCfor BOPPcounter-rotating twin-screw

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for WPC, for BOPP

- Number of screws

- counter-rotating twin-screw

- Output

Max.: 1,200 kg/h

(2,645.5471 lb/h)Min.: 70 kg/h

(154.3236 lb/h)- Screw diameter

Max.: 108 mm

(4.3 in)Min.: 41 mm

(1.6 in)- Maximum speed

400 rpm, 600 rpm

(2,513 rad.min-1, 3,770 rad.min-1)- Power

Max.: 355 kW

(482.67 hp)Min.: 30 kW

(40.79 hp)

Description

USEON TDY Series Compounder is specially made for reaction and devolatilization.

USEON has affluent experiences and hold unique and rich practices in reaction and devolatilization extrusion. The extraordinary working principles of counter rotating twin screw extruder occupy a particular niche in the extrusion process. We have developed some special screw elements and barrels to fulfill the individual processing task.

Due to its unique working principle, the relative line speed is low, so that the material can be processed under very low shear force and fast exchange rate of material turn over. The increased material surface area associates with the vacuum system, resulting in a more ideal devolatilization performance.

Typical Application

Polymer reactive extrusion

Polymer devolatilization

WPC inline compounding extrusion

BOPP/BOPET/BOPA film recycle

PSF/POY/BCF fiber recycle

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other USEON Technology Limited products

Compounding Extrusion

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Plastic sheet extrusion line

- Twin-screw screw extruder

- Multilayer extrusion line

- Plastic pelletizer

- Polypropylen extrusion line

- Single-screw screw extruder

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- PVC screw extruder

- Single layer extrusion line

- Laboratory screw extruder

- PE screw extruder

- ABS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.