- Production Machines

- Plastics Processing

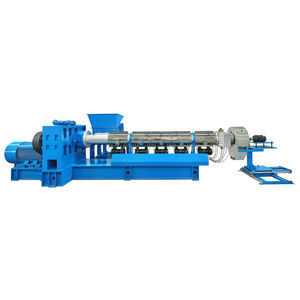

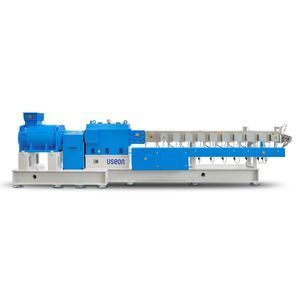

- Compounding extruder

- USEON Technology Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Compounding extruder SAT seriesfor WPCfor PVCfor EVA

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for PVC, for EVA, for WPC, for HFFR, for PEX, for XLPE

- Number of screws

- twin-screw

- Other characteristics

- for masterbatch, for cables

- Output

Max.: 2,500 kg/h

(5,511.5566 lb/h)Min.: 200 kg/h

(440.9245 lb/h)- Screw diameter

Max.: 240 mm

(9.4 in)Min.: 51.4 mm

(2 in)- Maximum speed

Max.: 600 rpm

(3,770 rad.min-1)Min.: 90 rpm

(565 rad.min-1)- Power

Max.: 500 kW

(679.81 hp)Min.: 55 kW

(74.78 hp)

Description

Certain polymers require pelletizing to be carried out under conditions without water and moisture, so that the extrusion system should have sufficient cooling capacity to cater for in this process; some materials are sorted into shear-sensitive or heat-sensitive categories. SAT tandem extrusion system is deigned for such processes. Primary twin screw extruder provides mixing and dispersion without over-shear, lower speed single screw extruder provides enough cooling and pressure accumulation.

Catalogs

Other USEON Technology Limited products

Extruder & Compounding Machines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Plastic sheet extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- ABS screw extruder

- PVC screw extruder

- Single layer extrusion line

- Laboratory screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.