- Production Machines

- Plastics Processing

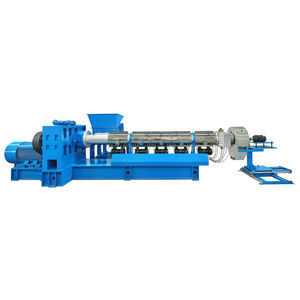

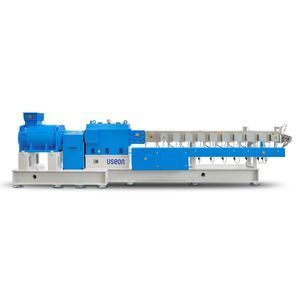

- Compounding extruder

- USEON Technology Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Compounding extruder for PVCfor PPfor PE

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for PP, for PVC, for PE, for PET, for PS, for PA, for EVA, for PLA, for TPE, for PBT

- Number of screws

- twin-screw, single-screw, triple screw

- Other characteristics

- for masterbatch

Description

USEON is a top plastic extruder manufacturer in China. We can provide complete masterbatch production lines.

We supply turn-key solutions to your masterbatch compounding projects. This includes material handling, dosing, extrusion, pelletizing and other aspects.

Volumetric feeding system

Weigh the raw material separately according to the formula

Place all the materials into the high-speed mixer for 5~10minutes

Discharge the material into the spiral loader

Load the material into the hopper of volumetric feeder

Loss-in-weight feeding system (automatically and higher accuracy)

Put the raw material into each tank on the ground.

Vacuum loader will convey each component into the storing silo.

The raw material will fall into the loss-in-weight feeder automatically. The feeding system will feed the material separately into extruder according to your formula setting one the HMI.

Extruders for Filler Masterbatch Compounding

According to your application and output, there’re many different choices of extruders.

Kneader + Single Screw Extruder

Kneader + Twin Screw Extruder

Extruders for Color Masterbatch Compounding

Color Masterbatch can be used for any types of polymers and all kinds of products. USEON have rich experiences in providing color masterbatch making machines.

One extruder can generate many types of additives. So, it requires a fast cleaning type strand die plat for any changes to the formula.

Catalogs

No catalogs are available for this product.

See all of USEON Technology Limited‘s catalogsOther USEON Technology Limited products

Extruder & Compounding Machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.