- Production Machines

- Plastics Processing

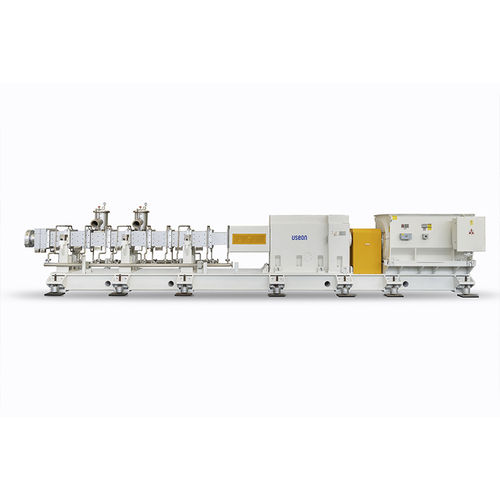

- USEON Technology Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Rubber recycling devulcanizing machine SAT series

Add to favorites

Compare this product

Characteristics

- Options

- for rubber recycling

Description

Our rubber devulcanization technology is thermo-mechanical way.

Process

Process 1:

Just do Devulcanization process for the rubber and add 5~10% into the new rubber for new tire or sheet application, without affecting the properties of new rubber.

Process 2:

Do Devulcanization and Compounding together. Adding the Polymer at the second stage extruder and with under water pelletizing system. This is similar with TPE compounding process.

Details of One Projcet

Raw Materials

PP/PE + Tire recycling powder (with the particle size less than 3mm and moisture less than 5%) + Paraffinic oil

Process Flow

Loss in weight feeding system → SAT75 twin screw extruder → SAT95 twin screw extruder → underwater pelletizing system

Output

1000kg/h

VIDEO

Catalogs

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- Cast-film extrusion line

- Twin-screw extrusion line

- ABS screw extruder

- PVC screw extruder

- Laboratory screw extruder

- Single layer extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.