Vibrating level switch Vibranivo® VN 2000electromechanicalfor silicic acidfor bulk materials

Add to favorites

Compare this product

Characteristics

- Technology

- vibrating, electromechanical

- Medium

- for silicic acid, for bulk materials

- Applications

- for the food industry, for hazardous locations, for hygienic applications, for non-conductive vessels

- Approvals

- CCC-Ex, FM/CSA, IEC-Ex, INMETRO, KCs, TR-CU, ATEX

- Material

- stainless steel

- Mounting

- vertical, horizontal, threaded, flange, side-mount

- Other characteristics

- compact, high-temperature, rapid installation, high-pressure, with display, with protective tube, flameproof, IP66, explosion-proof, intrinsically safe, chemical-resistant, corrosion-resistant

- Process temperature

Max.: 150 °C

(302 °F)Min.: -40 °C

(-40 °F)- Process pressure

Max.: 16 bar

(232.06 psi)Min.: -1 bar

(-14.5 psi)

Description

Level detection with Vibration fork

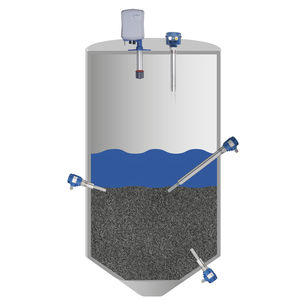

The Vibranivo® - vibrating fork for point level measurement, with its robust stainless steel extension and high sensitivity, is widely used in storage silos and process vessels.

The Vibranivo® vibration level switch is robust, easy to operate and can, via its series range, be precisely configured for each application.

Electronically stimulated piezos cause the fork to vibrate. As soon as the sensor is covered with material, the vibration is dampened and the resulting electrical current change causes the output signal to switch. Once the material level falls below the sensor, it is free to vibrate again and the output signal is reset.

International approvals for use in hazardous locations (gas and dust).

FEATURES:

• - Robust design

• - Surface-polished oscilating fork (0.75 m)

• - High sensitivity, for bulk weights < 5 g / l

• - Orientation markings and rotatable housing facilitate easy installation

• - Potted electronics (NAMUR)

• - Continuous self-diagnosis and functional testing

• - Remote housing to withstand strong vibrations

OUR SOLUTIONS FOR:

• - Extremely light product density

• - Pneumatic filling

• - Limited space

• - Vibration within the vessel

• - High reliability requirements

• - High hygienic requirements

• - Explosive environments

• - Sediment levels in liquids

VIDEO

Catalogs

Vibranivo® VN 2000 / VN 6000

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- UWT Level Control level switch

- UWT Level Control level sensor

- UWT Level Control liquid level switch

- UWT Level Control liquid level sensor

- UWT Level Control analog level sensor

- UWT Level Control protection level level switch

- Level transmitter

- UWT Level Control stainless steel level switch

- Liquid level transmitter

- UWT Level Control digital output level sensor

- UWT Level Control threaded level switch

- Analog level transmitter

- UWT Level Control storage tank level sensor

- Liquids level indicator

- Tank level detector

- Plastic level switch

- Digital output level transmitter

- UWT Level Control stainless steel level sensor

- IP68 level probe

- UWT Level Control solid level switch

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.