Level sensor with interface measurement NivoCapa® NC 8000capacitivefor waterfor fuel

Add to favorites

Compare this product

Characteristics

- Technology

- capacitive

- Medium

- for water, for fuel, for oil, for wastewater, for sludge, for high-viscosity liquids, for corrosive liquids, for aggressive liquids, for conductive liquids, for AdBlue

- Interface

- 4-20 mA, 2-wire, digital output

- Applications

- for fill monitoring, for storage tanks, fuel tank, for the food industry, for OEM, rugged, high-temperature, for food applications, for industrial applications, for corrosive environments, for the food and beverage industry, for marine applications, for silos, for sumps, for basin, for hazardous areas, for hygienic applications, for the pharmaceutical industry

- Approvals

- FM/CSA, IEC-Ex, TR-CU, INMETRO

- Other characteristics

- rugged, stainless steel, compact, flange-mount, flexible, maintenance-free, chemical-resistant, ATEX, side-mount, with interface measurement, FM/FMC, IP67, programmable, with digital display, with LED indicator, loop-powered, corrosion-resistant

- Level range

Max.: 25,000 mm

(984.25 in)Min.: 300 mm

(11.81 in)- Process pressure

Max.: 35 bar

(507.63 psi)Min.: -1 bar

(-14.5 psi)- Process temperature

Max.: 400 °C

(752 °F)Min.: -40 °C

(-40 °F)

Description

Application area

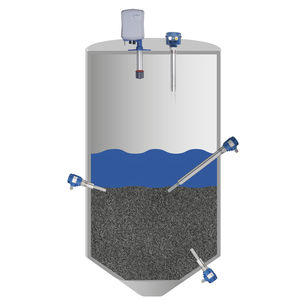

The capacitive level sensor NivoCapa® 8100 is a simple and cost-effective solution for level measurement of liquids or oils. Interface measurement is possible as well. It can be used in large storage tanks, small process vessels, buffer tanks, hoppers, sumps, bypass or downtubes. The different gadget versions make installations from above and below possible and - due to remote housing - can also be used in vibrating environments or in areas of limited space.

Your benefit

• - Reliable measurement results even with viscous, adhesive medium due to "Active Shield" technology

• - "Inverse Frequency Shift" technology ensures precise measurement results

• - Maintenance-free sensor

Features:

- Robust design

- Chemical resistant PFA coating

- Active buildup compensation

- Fast reaction time

- Inverse frequency shift technology

- Potted electronics

- Integrated LCD display with diagnostic functions

- 2-wire electronics with 4 ... 20 mA output

OUR SOLUTIONS FOR:

• All types of liquids

• Condensation

• Very strong caking

• Aggressive materials

• High safety standard

• Explosive environments

VIDEO

Catalogs

NivoCapa® NC 8000

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- UWT Level Control level switch

- UWT Level Control level sensor

- UWT Level Control liquid level switch

- UWT Level Control liquid level sensor

- UWT Level Control analog level sensor

- UWT Level Control protection level level switch

- Level transmitter

- UWT Level Control stainless steel level switch

- UWT Level Control digital output level sensor

- Liquid level transmitter

- UWT Level Control threaded level switch

- Analog level transmitter

- UWT Level Control storage tank level sensor

- Liquids level indicator

- Tank level detector

- Plastic level switch

- Digital output level transmitter

- UWT Level Control stainless steel level sensor

- IP68 level probe

- UWT Level Control solid level switch

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.