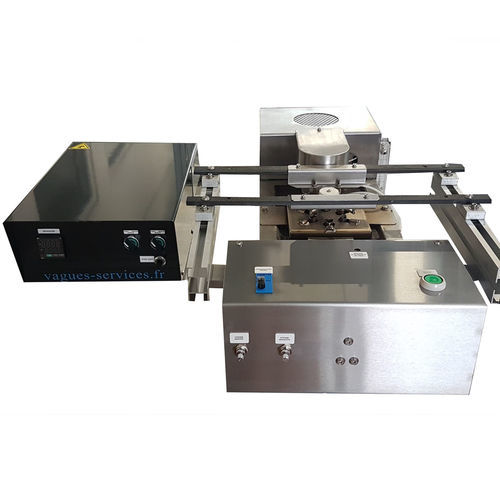

Mini-wave selective soldering machine MV 400for electronic componentsfor PCBdesoldering

Add to favorites

Compare this product

Characteristics

- Technique

- mini-wave

- Applications

- for electronic components, for PCB

- Other characteristics

- desoldering, electric

- Power

1,800 W

Description

• Dimensions Max PCB + Nozzle: PCB: 300 x 500 mm - Nozzle L x W: 125 x 90 mm

• Max temperature: 500 ° C

• Overall dimensions & Weight: Length: 570 mm - Width: 250 mm - Height: 200 mm - Empty weight: 25 Kg - Alloy: 20 Kg

• Electric Power & Voltage: 1800 W - 220V Mono

The Mini-Wave MV 400 is a selective soldering and desoldering station for through-hole components without affecting and damaging neighboring components.

This station is intended for electronic production and for repairing cards. It makes it possible to overcome manual operations which are very expensive.

The principle of the Mini-Wave brazing is to send the molten alloy to the surface of the nozzle at a predefined height with overflow. The presence of the alloy flow enables the component to be brazed or de-brazed. The nozzles are quickly interchangeable. The brazing or desoldering process is very simple to implement, fast and repeatable. The Mini-Wave is built all Titanium and compatible with ROHS lead free.

The design and production are made according to your needs, also made to measure.

Power: 1800W / Power supply: 400V

Alloy capacity: 20kg

Max temperature: 450 ° C

Maximum nozzle size (*): 70 × 70 mm

Warm-up timer

Simple adjustable IC holder

XYZ table with fine adjustment of the height adjustment

Pneumatic up-down with fine height adjustment + wave start sensor

Cycle start with pedal (available with dual display box)

Stainless steel bath cover

Nitrogen cover with pressure gauge, flowmeter, Titanium cover with diffuser (porous stainless steel) - Laser pointer

Activated carbon filter hood

Catalogs

CATALOG VAGUES SERVICES

138 Pages

Related Searches

- Soldering machine

- Automated soldering machine

- Printed circuit soldering machine

- Selective soldering machine

- Wave soldering machine

- Automatic selective soldering machine

- In-line soldering oven

- PCB selective soldering machine

- Compact soldering machine

- Brazing oven

- Wave selective soldering machine

- Electric soldering machine

- Automatic brazing machine

- Electronic component selective soldering machine

- Mini-wave selective soldering machine

- Small-scale production soldering oven

- Compact selective soldering machine

- Medium-scale production soldering machine

- Electric brazing machine

- Large-scale production soldering machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.