- Environment - Health - Safety

- Waste Treatment

- Vertical baling press

- Valvan Baling Systems NV

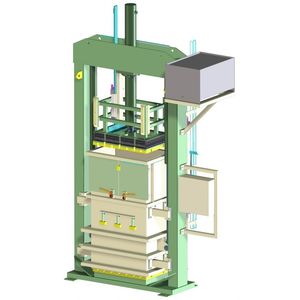

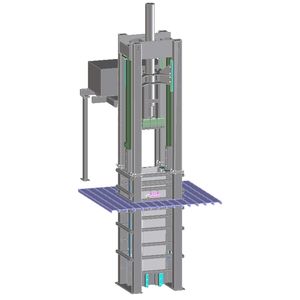

Vertical baling press FTCtop-loadingfor textilesautomatic

Add to favorites

Compare this product

Characteristics

- Orientation

- vertical

- Loading

- top-loading

- Applications

- for textiles

- Other characteristics

- automatic, downstroke

- Compression power

300 tf, 500 tf, 600 tf

Description

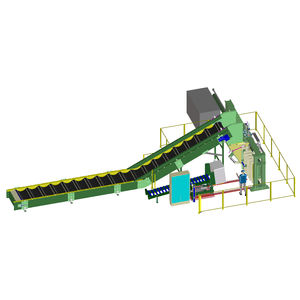

The FTC baling press is designed to pack single bumps into a bale. The bumps are stacked in a cart, which is loaded into the press by means of a shuttle. Once the cart is inside the press, the bumps are pushed into the press box.

The press box is equipped with a retaining device, which hold the bumps up, while a second cart is inserted. After filling, the shuttle removes the empty cart and the lower pressing plate transfers into the press. The press box lowers and then the bumps are pressed into a bale.

After the bale is formed, the press box is pulled up, so that the bale is free to be wrapped and strapped. Next the bale is taken out of the press by means of a bale removal system, and transferred on an evacuation roller conveyor.

As an option automatic wrapping and strapping can be added.

Catalogs

Valvan Baling Systems NV

13 Pages

Other Valvan Baling Systems NV products

Baling Presses Fibers

Related Searches

- Baling press

- Vertical chamber baling press

- Cardboard baling press

- Top-loading baling press

- Horizontal baling press

- Front-loading baling press

- Automatic baling press

- Paper baling press

- Plastic baling press

- Waste baling press

- Compact baling press

- Channel baling press

- Single-chamber baling press

- Textile baling press

- Bottle baling press

- High-capacity baling press

- High-density baling press

- Semi-automatic baling press

- High-power baling press

- Multi-chamber baling press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.