- Packing - Handling - Logistics

- Conveying

- Automatic sorter

- Valvan Baling Systems NV

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

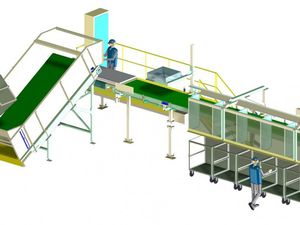

Automatic sorting system for textilesboxsplit tray

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- for textiles, box

- Other characteristics

- split tray

Description

For production requirements above 15 tons per shift, a custom-made box sorting system can be designed, suited to your production, space, sorting method and budget.

The basic idea is that a sorter in the first sorting operation has small boxes in front, so that the distances to throw are minimized in order to increase the production and offer an ergonomic workspace. The content of the boxes is emptied automatically and weighed, which reduces the handling cost significantly.

The box sorting system is a modular system, so production can be increased by adding more modules. Here are some examples of box sorting systems that we have recently built.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Valvan Baling Systems NV‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Feeder

- Roller rail conveyor

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Automatic sorting machine

- Automated feeder

- Feeding conveyor

- Rail transfer car

- Mobile conveyor

- Loading conveyor

- Weighing system

- Color sorting machine

- Big bag station

- Custom-made conveyor

- Pneumatic feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.