- Metrology - Laboratory

- Analytical Instrumentation

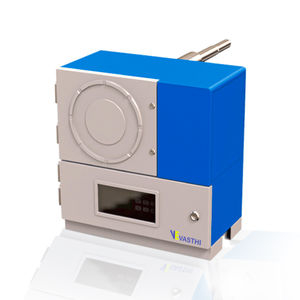

- Oxygen analyzer

- vasthi instruments

Oxygen analyzer electrolytepowerpressure

Add to favorites

Compare this product

Characteristics

- Measured entity

- oxygen, electrolyte

- Measured value

- power, pressure, flow

- Configuration

- in situ, in-line

- Technology

- zirconia

Description

Online Zirconia Oxygen Analyzer

A Choice of configuration is available. The most convenient and economical is a standard controller of Online Zirconia Oxygen Analyzer with the cell mounted on the rear.

Alternatively, there is remote sensor housing complete with flow meter and valve. where cable lengths and/or hazardous area conditions are an issue, the transmitter can be located in the sensor housing.

Super Oxv In situ High Temp Zirconia Probe:

Applications:-

Direct —fired furnaces (reheat , annealing, tunnel)

Glass furnace(side-fired ,end-fired ,float ,container and

fiberglass)

Power generation-boiler(gas-fired and coal-fired)

Ceramic and brick kilns

Petrochemical-after-burners, incinerators, package

boilers, sulfur burners.

Super Ox Specifications

Process variable range : 8.77 E — 23 to 20.9%

Temperature Range : 650 -1650 Deg. C

Sensor Impedance : less than 20 K ohms @ 920 Deg. C

Sensor Output : 0 to 1250 mVDC

Response time : less than 1 second

Sheath Material: 99 % Alumina or Silicon Carbide.

Super Ox Benefits:

Field performance cab be corroborated using external Verification port

Cooling air maintains positive pressure to ensure the integrity of electrical connections in harsh environments

Outer electrode is not “painted “on the zirconia electrolyte eliminating the antiquated “boot” design

Available in a number of standard lengths — 18″ [457

mm], 26″ [660 mm], 30″ [762 mm] and 36″ [915 mm]

“B”,”S”, and “R” thermocouples are available.

Catalogs

No catalogs are available for this product.

See all of vasthi instruments‘s catalogsRelated Searches

- Gas analyser

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Desktop analyzer

- Automated analyzer

- Dust analyzer

- Gas detector

- Process analyser

- Portable analyser

- Continuous analyser

- Water analyser

- Real-time analyser

- Oxygen analyser

- Compact analyser

- Industrial detector

- NDIR analyzer

- Digital analyser

- In-line analyser

- Temperature analyser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.