- Packing - Handling - Logistics

- Packing and Packaging

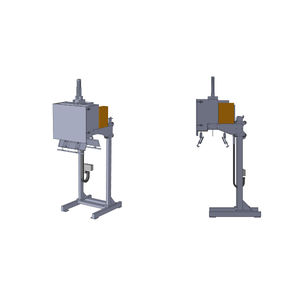

- Vertical bagging machine

- VCG Flüssigkeitsfüllmaschinen GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Vertical bagging machine VFBautomaticfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Operational mode

- automatic

- Application domain

- for the food industry

- Throughput

700 p/h

Description

Fully automatic bagging system for gusseted bags. This machine is used to package barbecue lighter, oven lighter, charcoal, grain etc.. It is particularly suitable for bulky or granular products and for the use of gusseted bags. The bags are opened under the filling spout and closed immediately after filling. They are then taken over by a bag gripper and transported into a bag closing station while the bag bottom is running on a conveyor belt. After being taken out of the bag dispenser the bags are always held right until the pneumatic gripper releases them in the bag closing device.

Different weighers and the dosing systems can be combined with this bagging machine and are chosen according to the products that are being bagged. It has been equipped with vibration chutes, belt dosing systems or dosing flaps. Equally the filling spout is is adapted to the products and bag sizes. The machine often comes with several filling spouts to account for vastly different bag sizes.

This machine can be combined with different bag closing systems and bags transport components to further automate the packing process. These can be integrated into the machine housing or as separate units. Machine parameters are:

Filling range: 1...10 kg (depending on design)

Bags: width 100-300 mm; length up to 600 mm (other sizes upon request)

Execution

• solid machine frame that can be used to place a weigher and dosing system and can be equipped with a maintenance platform

• discharge chute for weigher

• bag dispenser for standing bags or bags lying down

• pneumatic bag separation

• filling spout with closing flap

Other VCG Flüssigkeitsfüllmaschinen GmbH products

Products

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Filler for the food industry

- Automatic bagging machine

- Vertical bagging machine

- Bottle filler

- Food product filling machine

- Bagging machine for the food industry

- Volumetric filler

- Filling system for the chemical industry

- Sealer

- Container filler

- Heat sealer

- Piston filler

- Bag filler

- Automatic capper

- Weight filler

- Compact filler

- Powder filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.