- Products

- Catalogs

- News & Trends

- Exhibitions

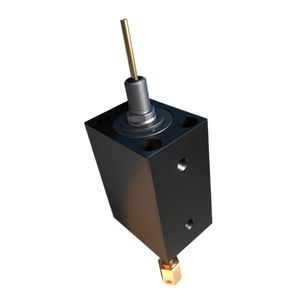

Tie-rod cylinder V215 CDhydraulicstainless steelsteel

Add to favorites

Compare this product

Characteristics

- Type

- hydraulic

- Technology

- tie-rod

- Material

- stainless steel, steel

- Norms

- ISO 6020

- Applications

- for die-casting applications

- Other characteristics

- compact

- Stroke

Max.: 250 mm

(9.843 in)Min.: 20 mm

(0.787 in)- Bore

Max.: 200 mm

(7.87 in)Min.: 50 mm

(1.97 in)- Pressure

Max.: 215 bar

(3,118.3 psi)Min.: 140 bar

(2,030.5 psi)- Force

Max.: 50,240 daN

Min.: 1,570 daN

- Speed

0.1 m/s, 0.8 m/s

(0.33 ft/s, 2.62 ft/s)

Description

The V215CD includes tie-rod hydraulic cylinders following the international UNI ISO 6020/2 fixing size norms. The standard version includes piston bores from 50 to 200 mm, and strokes from 1 to 1500 mm. V215CD cylinders offer long strokes and linear movements with one rod-end (no passing-through rod). They are composed of two heads, one central tube, and 4 closing tie-rods.

V215CD hydraulic cylinders can be employed to move components—such as carts, pins, and plugs—that might produce undercuts in aluminum die-casting molds. In-line pinned fixings are available on either front and rear heads. Also, front and rear adjusting flanges are available as well.

The front cartridge sealing system includes one scraper, 3 bush guides, and 2 NBRH O-Rings for temperatures up to 150°C. These components allow the cylinder sealing system to last over long periods of time.

These hydraulic cylinders are compatible with water-glycol mixtures.

The cylinder piston can include a magnet with a powerful attraction force. The piston stroke can be controlled by means of adjustable electronic sensors, able to read the surrounding magnetic field. Moreover, mechanical sensors are also available for these cylinders, as well as inductive and encoder ones. Signals can be transferred to the plastic injection machine. The maximum working temperature for magnetic and inductive sensors is 80° C., whereas mechanical ones can withstand temperatures up to 180°C.

Catalogs

V215CD

24 Pages

Related Searches

- Cylinder

- Double-acting cylinder

- Hydraulic cylinder

- Standard cylinder

- Compact cylinder

- Industrial cylinder

- ISO cylinder

- Anodized aluminum cylinder

- Stainless steel cylinder

- Steel cylinder

- Cylinder with piston rod

- Precision cylinder

- Micro cylinder

- Heavy load cylinder

- Double-rod cylinder

- Integrated cylinder

- Tie-rod cylinder

- Block cylinder

- Small cylinder

- Guide cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.