- Products

- Catalogs

- News & Trends

- Exhibitions

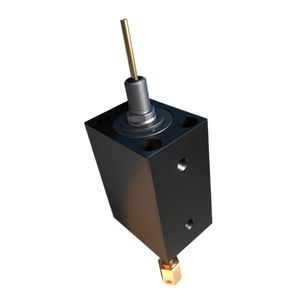

Self-locking cylinder V270 CGhydraulicwith piston roddouble-acting

Add to favorites

Compare this product

Characteristics

- Type

- hydraulic

- Technology

- with piston rod

- Configuration

- double-acting

- Applications

- for die-casting applications

- Other characteristics

- precision, integrated, small, self-locking

- Stroke

Max.: 200 mm

(7.874 in)Min.: 30 mm

(1.181 in)- Bore

Max.: 84 mm

(3.31 in)Min.: 30 mm

(1.18 in)- Pressure

100 bar

(1,450.4 psi)- Force

Max.: 4,923 daN

Min.: 565 daN

- Speed

0.1 m/s

(0.33 ft/s)

Description

The V270CG series offers self-locking hydraulic cylinders, with a special locking system between the cylinder rod and body. Round-shaped, these double-effect cylinders can be configured for linear-movement strokes, both short and medium. The standard version of these cylinders includes piston bores from 30 to 84 mm, and strokes from 30 to 150 mm.

The main application for hydraulic cylinders V270CG is to accurately move and lock mold components—such as carts, pins and plugs—that might produce undercuts or that are used to withstand injection pressure. These cylinders can be used to avoid burrs from plastic material between pins and molds. It also allows to easily adjust the pre-load of the rod, saving both time and money.

The main strength of this mechanical-locking hydraulic cylinders is the ratio between its compactness and its mechanical holding force. The reliability of this locking system is proved by its high performance in over 25 years of applications. Moreover, its price is among the most inexpressive in all the world. The cartridge sealing system includes a scraper and two Viton O-rings, granting a lasting and excellent sealing over time.

The V270CG sensors are inductive ones, mounted within the piston chamber. These cylinders can reach a maximum temperature of 130° C. (without sensors) and a maximum temperature of 80°C. (with sensors). Their maximum hydraulic pressure is 270° C., and their maximum speed is 0.1 m/s.

VIDEO

Catalogs

V270CG

18 Pages

Related Searches

- Cylinder

- Double-acting cylinder

- Hydraulic cylinder

- Compact cylinder

- Standard cylinder

- ISO cylinder

- Industrial cylinder

- Anodized aluminum cylinder

- Stainless steel cylinder

- Steel cylinder

- Cylinder with piston rod

- Precision cylinder

- Micro cylinder

- Heavy load cylinder

- Double-rod cylinder

- Integrated cylinder

- Tie-rod cylinder

- Small cylinder

- Block cylinder

- Guide cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.