- Products

- Catalogs

- News & Trends

- Exhibitions

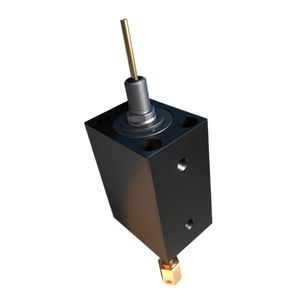

Hydraulic cylinder V400CLwith piston rodsteelstandard

Add to favorites

Compare this product

Characteristics

- Type

- hydraulic

- Technology

- with piston rod

- Material

- steel

- Other characteristics

- standard, integrated

- Stroke

Max.: 200,000 µm

(7.874 in)Min.: 10 µm

- Bore

Max.: 100 mm

(3.94 in)Min.: 16 mm

(0.63 in)- Pressure

400 bar

(5,801.5 psi)- Force

Max.: 19,625 daN

Min.: 161 daN

- Speed

0.1 m/s

(0.33 ft/s)

Description

The v400CL series includes short-stroke hydraulic cylinders featuring just one cartridge and one single-ended rod. The standard version includes piston bores from 16 to 100 mm, and strokes from 10 to 200 mm. These cylinders are mainly employed when internal room within cylinders is extremely reduced. Two cartridge fixings are available— the first one is threaded, whereas the second flange features 4 passing-through holes.

Vega Cylinders manufactures hydraulic cylinders for molds, and the main application of V400CL cylinders is moving all those components—such as carts, pins, and plugs—that might cause undercuts in plastic injection molds. V400CL rods and pistons are made of high-quality chromium-molybdenum steel, with no moils. The cartridge sealing system includes one scraper, 3 bush guides, and 2 Viton O-Rings. These components allow the cylinder sealing system to last over long periods of time.

They are compatible with ISO VG 46 mineral oils or water-glycol mixtures.

The maximum working pressure of these cylinders is 400 bars, and the maximum delivery goes from 7 to 45 l/min.

Vega Cylinders offers a one-year long warranty for its cylinders, granting full support all over the world.

Moreover, thanks to the full stock of Vega, delivery times are greatly reduced. These short-stroke hydraulic cylinders can also be customized by sending a special project to Vega via e-mail (info@vegacylinders.it).

These cylinders cannot be tested on hydraulic workbenches.

Related Searches

- Cylinder

- Double-acting cylinder

- Hydraulic cylinder

- Compact cylinder

- Standard cylinder

- ISO cylinder

- Industrial cylinder

- Anodized aluminum cylinder

- Stainless steel cylinder

- Steel cylinder

- Cylinder with piston rod

- Precision cylinder

- Micro cylinder

- Heavy load cylinder

- Double-rod cylinder

- Integrated cylinder

- Tie-rod cylinder

- Small cylinder

- Block cylinder

- Guide cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.