- Products

- Catalogs

- News & Trends

- Exhibitions

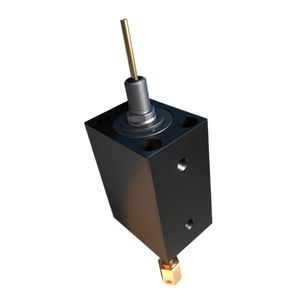

Hydraulic cylinder V450CMwith piston roddouble-actingsteel

Add to favorites

Compare this product

Characteristics

- Type

- hydraulic

- Technology

- with piston rod

- Configuration

- double-acting

- Material

- steel

- Protection class

- robust

- Other characteristics

- compact, standard, block, high-pressure, in-line

- Stroke

Max.: 200 mm

(7.874 in)Min.: 10 mm

(0.394 in)- Bore

Max.: 100 mm

(3.94 in)Min.: 16 mm

(0.63 in)- Pressure

450 bar

(6,526.7 psi)- Force

Max.: 23,550 daN

Min.: 161 daN

- Speed

0.1 m/s

(0.33 ft/s)

Description

The V450CM series offers short-stroke compact hydraulic cylinders with linear movement and a steel body with a single rod-end (no passing-through rod). The standard version includes piston bores from 16 to 100 mm and strokes from 10 to 200 mm. Thanks to their line fixings, these cylinders can be installed by means of passing-through holes by according to their lengths, or by means of pinned holes and a key.

Vega Cylinders manufactures high-pressure hydraulic cylinders for molds, and the V450CM series is focused mainly on moving all those components—such as carts, pins and plugs—that might cause undercuts in plastic injection molds. Its also suitable for moving ejection plates in injection molds.

The main strength of these cylinders is the ratio between compactness and hydraulic resistance to extreme pressures. The reliability of this locking system has been proved on injection molds in over 25 years of applications.

This heavy duty hydraulic cylinder offers a high-workability steel body, with a high-quality chromium-molybdenum steel rod and piston, with no moils. The cartridge sealing system includes a scraper and two Viton O-rings. These components allow the cylinder sealing system to last over long periods of time. V450CM cylinders are compatible with ISO VG 46 mineral and water-glycol mixtures.

The stroke of V450CM hydraulic cylinders can be controlled by means of inductive or mechanical switches, and signals can be directly transferred to the injection mold machine. The maximum working temperature is 80° C. for Cylinders with inductive switches, and 180° for mechanical switches.

VIDEO

Related Searches

- Cylinder

- Double-acting cylinder

- Hydraulic cylinder

- Standard cylinder

- Compact cylinder

- Industrial cylinder

- ISO cylinder

- Anodized aluminum cylinder

- Stainless steel cylinder

- Steel cylinder

- Cylinder with piston rod

- Precision cylinder

- Micro cylinder

- Heavy load cylinder

- Double-rod cylinder

- Integrated cylinder

- Tie-rod cylinder

- Block cylinder

- Small cylinder

- Guide cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.