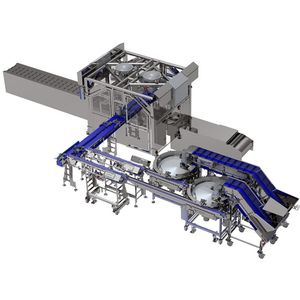

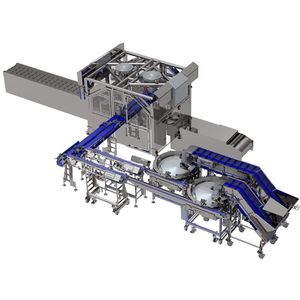

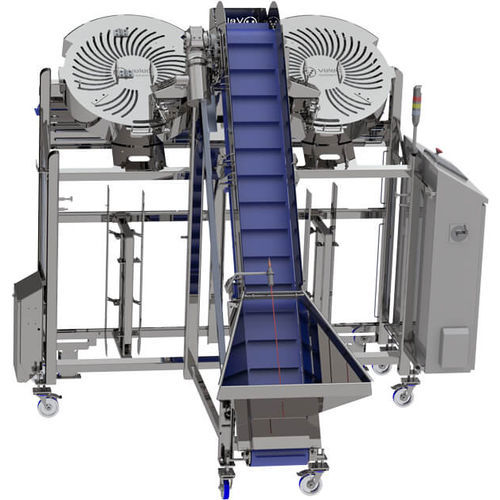

Inclined bagging machine 2PA 800flow-packthermoformingautomatic

Add to favorites

Compare this product

Characteristics

- Type

- inclined

- Technology

- flow-pack, thermoforming

- Operational mode

- automatic

- Application domain

- for the food industry, for the cosmetics industry

- Product applications

- for bulk materials

- Other characteristics

- high-speed, compact

- Throughput

Max.: 360 p/min

Min.: 180 p/min

Description

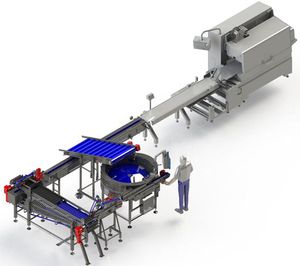

The VELEC dry sausage bells machine has been developed for the most demanding customers looking for sanitation and gentle packing of their dry sausage bellss. It is an extremely versatile system and an easy to use dry sausage bells machine.

Sanitation of the VELEC dry sausage bells machine

The VELEC’s engineering team has concentrated all its effort to make the VELEC dry sausage bells machine the most hygienic design solution available on the market.

Every single details of our VELEC dry sausage bells machine fulfil and overpass the recommendations of the meat Industry and the best practices of the European Hygienic Engineering & Design Group (EHEDG).

As an example, our VELEC dry sausage bells machine have the following key characteristics:

• Fully manufacture in stainless steel, any single part of our VELEC dry sausage bells machine is glass bead finished to have minimal surface roughness for a very hygienic solution.

• To avoid water retention area, the VELEC dry sausage bells machine is designed in a way to avoid any horizontal flat surface and to have only inclined surfaces.

• The VELEC dry sausage bells machine is fully welded with very minimal quantity of bolts, nuts and timing screws, areas which are difficult to access and clean.

• Contrary to our competitors, the VELEC dry sausage bells machine has absolutely no hollow tubing construction.

• The VELEC dry sausage bells machine use only IP69K components from sensors to actuators, fully stainless steel (no aluminum),

• Because modular belts are well known for all the small holes and areas which are impossible to clean, the VELEC dry sausage bells machine use exclusively smooth belts.

VIDEO

Catalogs

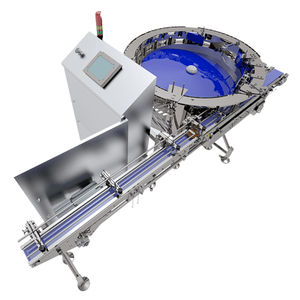

2PA800 cellular counter

2 Pages

Olives depositor

2 Pages

Related Searches

- Bagging machine

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bulk material bagging machine

- Bagging machine for the food industry

- Case packer

- Automatic case packer

- Compact bagging machine

- Weight bagging machine

- High-speed bagging machine

- Bagging machine for the cosmetics industry

- Vertical case packer

- Compact case packer

- Case packer for the food industry

- Inclined bagging machine

- High-speed case packer

- Food case packer

- Cosmetic product case packer

- Thermoforming bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.