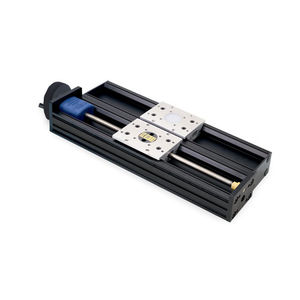

Linear stage BiSlide®PC1motorizedmanualmulti-axis

Add to favorites

Compare this product

Characteristics

- Orientation

- linear

- Type

- motorized, manual

- Number of axes

- multi-axis

- Other characteristics

- aluminum, for large loads, belt-driven

- Stroke

203.2 cm

(80 in)- Repeatability

4 µm

Description

The system features two identical Velmex linear BiSlide Assemblies coupled with a timing belt to drive synchronous operation. It can handle loads to 600 lbs. (272 kg) and is available in many standard lengths up to 80 inches (203.2 cm).

The Parallel-Coupled BiSlide Assembly is available in both manual and motor-driven models. The motorized models feature a double shaft motor on one slide and a heavy-duty bearing assembly on the other slide. The manually-operated versions have the bearing assembly on both slides. A knob and crank drives the timing belt which in turn drives the lead screws.

It is possible to also parallel-couple Belt-Driven BiSlides. While Belt-Driven BiSlides typically handle lighter loads and faster speeds, the advantages of both systems can be incorporated into one. By doing so you increase the size of the payload the Belt-Drive system can handle while at the same time, increasing the speed and the traverse of the Parallel-Coupled BiSlide. Belt-driven systems feature a drive shaft coupling in place of the timing belt to synchronized the operation of the parallel BiSlides.

Constructed with hard-coat anodized, aluminum dovetail ways and smooth motion PTFE linear bearings; BiSlide Assemblies deliver higher rigidity for longer life and more precise movement. Longer traverses include specially-designed separators mounted perpendicular to the base to keep the system in parallel and add extra stability. The entire system is comprised of our proven BiSlide I-beam design and has all the same features of renown Velmex BiSlide stages.

Catalogs

No catalogs are available for this product.

See all of VELMEX, Inc.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.